Materials / Functional Plastics Products

Bioplastics Highlighted in the Resource Circulation Strategy for Plastics

1. What Is the Resource Circulation Strategy for Plastics Formulated in May 2019?

Background

Plastics have brought tremendous convenience to our lives. The performance of plastic helps reduce food loss and improves energy efficiency. At the same time, plastics also pose global issues. Plastics manufacture consumes exhaustible resources such as fossil resources and offer low overall effective global utilization compared to other materials. More than several million tons of plastic waste enter our oceans every year.

Formulation of the Resource Circulation Strategy for Plastics

Against this background, Japan set forth the Resource Circulation Strategy for Plastics in May 2019. The core principle of this strategy is “3Rs + Renewable.” The following key goals are specified:

(1) Actively reduce wasteful use of resources by rationalizing avoidable use of plastics such as single-use container packaging and products.

(2) Switch from plastic container packaging and products to recycled and recyclable materials to increase sustainability.

(3) Use plastic products for as long as possible.

(4) Establish cyclic use (reuse by recycling or energy use through heat recovery where recycling is technically or economically impractical) by rigorously separating and collecting plastics after use via an effective and efficient recycling system.

Milestones Used in the Resource Circulation Strategy

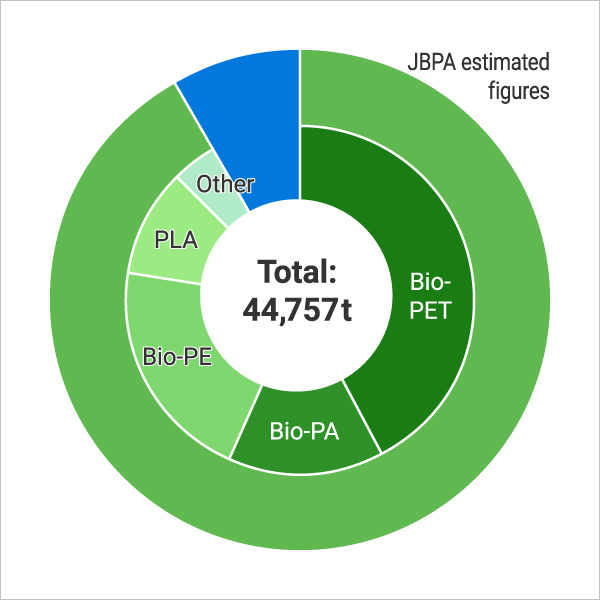

The targets of the Resource Circulation Strategy for Plastics include doubling recycling by 2030 and maximizing use of biomass plastics (approximately two million tons). At present (2018), the volume of biomass plastics used in Japan is 44 thousand tons. A Bioplastic Adoption Roadmap has been established to set forth detailed approaches toward applications and materials and to promote increased adoption after examining current conditions and issues.

Milestones

| Reduce | Reduced total outflow of single-use plastics by 25% by 2030 |

| Reuse and Recycle | Adoption of designs that allow reuse and recycling by 2025 |

| Reuse and recycling of 60% of container packaging by 2030 | |

| Achievement of effective use through 100% reuse or recycling of used plastic by 2035 | |

| Recycle and Biomass Plastics | Recycling doubled by 2030 |

| Use of approximately two million tons of biomass plastics by 2030 |

Amount of biomass plastics used in Japan

2. What Are Bioplastics?

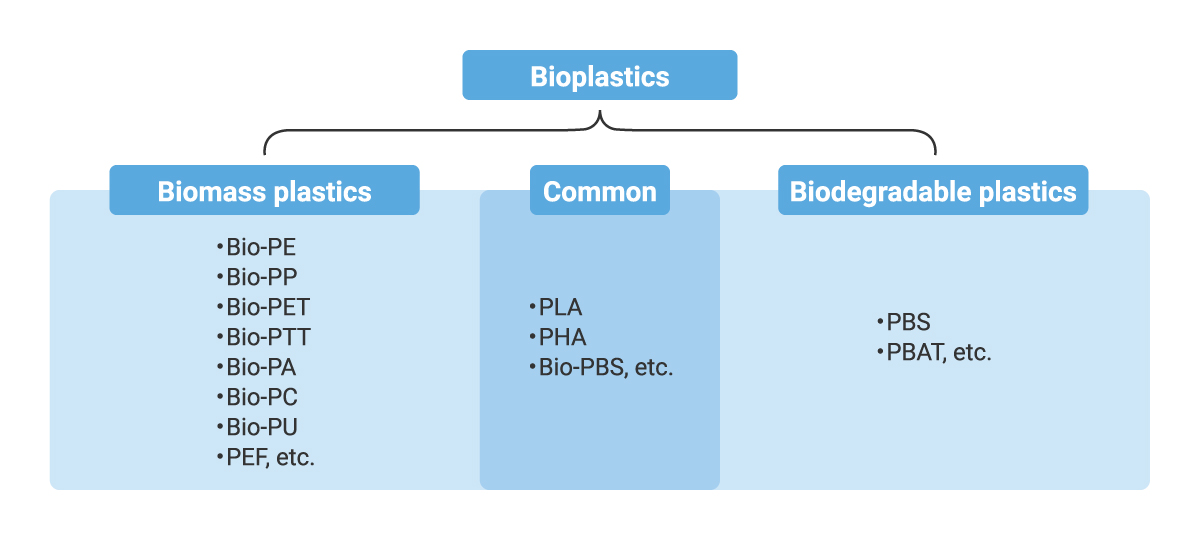

One promising solution to the issues related to plastics is bioplastics. Bioplastics is the general term for both (1) biodegradable plastics that can be decomposed by microorganisms and (2) recyclable biomass plastics made from plant-based organic resources without fossil resources—an area in which Iwatani’s participation began early.

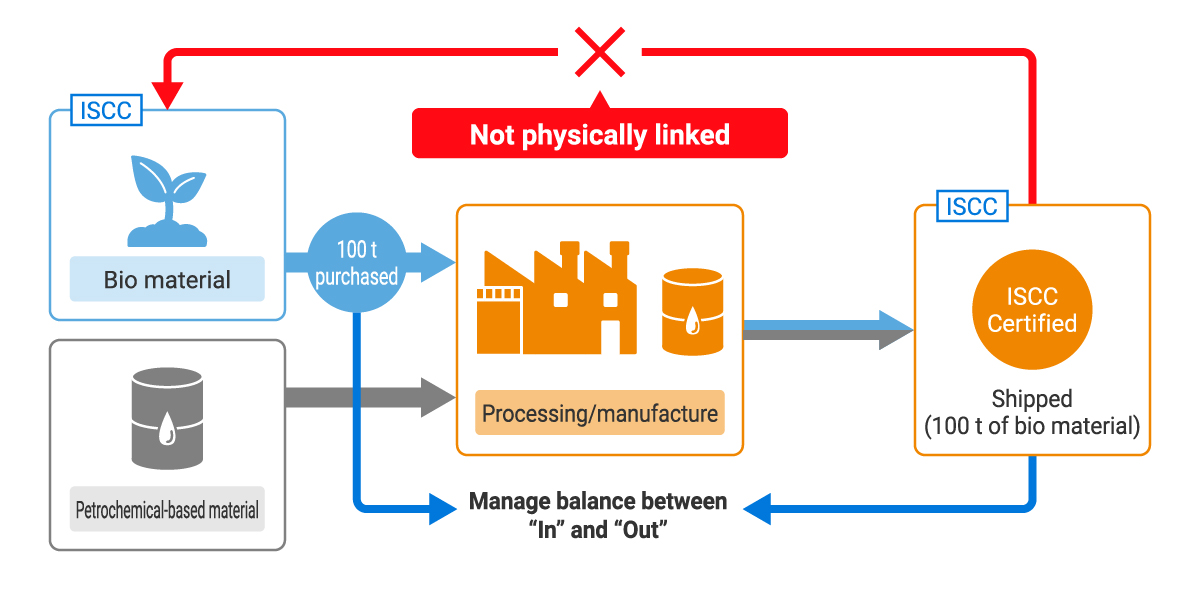

3. What Is the Mass Balance Approach Used to Promote the Use of Biomass?

One effective way to achieve the targets set forth in the Resource Circulation Strategy for Plastics is to adopt biomass plastics and materials recycled from waste plastic based on the mass balance approach. With conventional bio certification (segregation), only resin that uses entirely bio resources can be called “bio”; products that include 100% certified material can be labeled “Derived from 100% sustainable certified resources.” The mass balance approach allows mixing petrochemical-based materials with bio materials during production processes. The proportion of bio materials in the raw materials used is assigned to the final product. For example, if 100 tons of certified material are purchased, the amount of products that can be produced from that 100 tons can be shipped as ISCC MB certified products. Managing the overall balance between “In” (purchased amount of bio material) and “Out” (amount of certified resin sold) enables even petrochemical products to be shipped as 100% biomass.

Mass balance approach

Product List

-

Bio-PET Resins

Bio-PET resins are manufactured using bio-based monoethylene glycol (bio-MEG) refined from molasses, a byproduct of sugar cane processing, as a raw material instead of MEG derived from petrochemicals. This means that some 30% of the PET resin composition can be made up of plant-based materials. Lower costs can be achieved by blending this with conventional petrochemical PET. This has achieved an overall confirmed reduction (offsetting) in greenhouse gases of 21%. Practical applications: Beverage bottles, condiment bottles, cosmetics containers, films, sheets, etc.

-

Aluminum Catalyst PET Resins

Aluminum catalyst PET resin is less susceptible to color and property alteration due to heat treatment during recycling for excellent recyclability. It’s ideal for use in recycled bottles for beverages, an application that requires both moldability and transparency, to promote bottle to bottle recycling. As a material with low impact on the environment and the human body, aluminum promotes sustainable resource procurement amid growing awareness of environmental issues.

-

Bio-PP/Bio-PE/Bio-PS Resins

These bio-PP and bio-PE resins manufactured from hydrogen carbide derived from waste materials and residue oil by Neste in Finland are ISCC-certified, with guaranteed 100% biomass content. Being mass balance products, they have quality identical to petrochemical products, allowing samples to be furnished immediately. They generate approximately 75% less CO2 emissions compared to standard petrochemical products. Iwatani issues an ISCC certificate to customers with each order, allowing customers to apply for carbon tax exemptions in European countries.

-

Marine-Biodegradable Resins

Iwatani is active in developing and offering products that use marine-biodegradable resins for single-use items such as drinking straws, shopping bags, cutlery, and food container packaging. As certified marine-biodegradable materials, polyhydroxyalkanoates (PHA) are polymers formed from vegetable oils by a fermentation process using bacteria. They are similar in appearance to plastics and show particularly high promise among plant-based materials for their physical properties, with a wide range of applications expected.

Please inquire for more information.

Functional Plastics Products Department

Services / Products

Resources & Advanced Materials Top

- Zr (Zirconium) Compounds

- Ti (Titanium) Compounds

- PKS (Palm Kernel Shells)

- Wood Pellet/Torrefied Wood Pellet

- Al (Aluminum) Compounds

- Mg (Magnesium) Compounds

- Phenolic Resins

- Carbon Black

- Fe (Ferrum)

- Rare Earth

- Se/Te (Selenium/Tellurium) Compounds

- Sr (Strontium) Compounds

- Si (Silicon) Compounds

- Ba (Barium) Compounds

- Co (Cobalt) Compounds

- Ta/Nb (Tantalum/Niobium) Compounds

- Ga (Gallium) Compounds

- W (Tungsten) Compounds

- Mo (Molybdenum) Compounds

- Li/Cs/Rb (Lithium/Cesium/Rubidium) Compounds

- Ni (Nickel)

- Epsilon Iron Oxide (Nanoparticles)

- Ceramic Shapes

- Ceramic Honeycomb

- Catalyst Carriers

- Urea

- Stainless Steel

- Aluminum

- Copper/Copper Alloys

- Surface Treated Steel Sheet

- Precision Stainless Steel

- Functional Aluminum Foil

- Hydrogen-Refueling Station Materials

- Clad Metal

- High Alloy Steels/Nickel Alloys

- Magnesium Alloys

- Highly Functional Stainless Steel Foil

- Non-magnetic Stainless Steel

- Beryllium Copper

- Titanium

- Wire Processed Products

- Display Furniture

- Carts

- Heat Treatment Jigs/Cleaning Jigs

- Metal Etching

- FRP (Fiber Reinforced Plastics) Tanks

- Precision/Ultra-Precision Slitting

- Precision Press Processing

- Insert-Molded Articles

- Nursing Care Products

- Secondary Metals

- Eyeglass Parts

- Cast-Iron Pipes

- CFRTP (Carbon Fiber Reinforced Thermoplastics)

- Bonded Dissimilar Materials

- Cu-Fe Alloys

- Medical Titanium Material

- Low-Carbon Aluminum

- Film Slitting Business

- High-Impact Absorbent Acrylic Foam ISR-ACF Series

- Thin Film Heat Dissipating Sheet

- Rework Foam Tape

- Silicone OCA for Foldables

- Silicone OCA for Vehicle Displays

- Optical Urethane Protective Film ISR-TSU Series

- Shock Absorption Sheets ISR-DP Series

- Electric Peeling Tape

- Ultrathin Adhesive Tape

- Low Environmental Impact Protective Film (Recycled Optical PET Protective Film)

- Differential Tape (AB Tape)

- Heavy Water/Deuterium Compounds

- Battery Internal Materials

- Cylindrical Battery Materials

- Square Battery Materials

- Pouch Battery Materials

- Electronic Component Materials

- Semiconductor/HDD Materials (High-Purity Metal, High Functional Packaging Materials)

- Moistureproof Materials/Antifoulants

- Subsidiary Materials for Batteries

- Fuel Cell Related