Materials / Metals

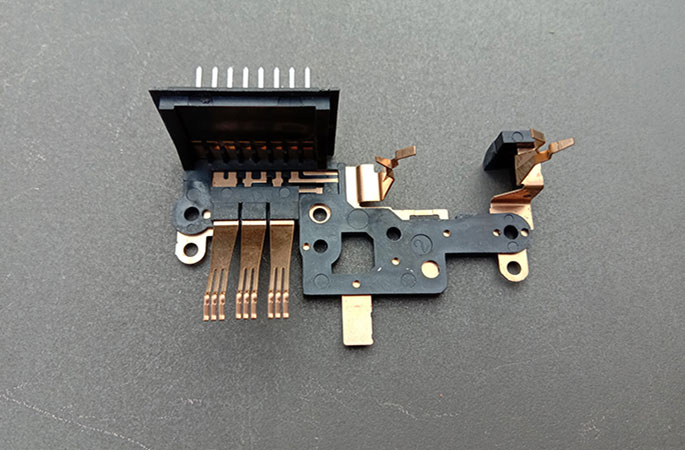

Insert-Molded Articles

Increased Molding Bond Strength With Reduced Processing Times

Insert molding is a press molding method in which metals and resins are combined. The resulting products are mainly used in electronic components, including vehicle-mounted components for next generation vehicles, and their usage is expanding across a wide range of fields and applications. Iwatani offers products whose entire manufacturing process, from pressing to insert molding, occurs at Iwatani facilities in Japan and overseas.

Iwatani’s Strengths

- 1. Entire process, from pressing to resin insert molding, is carried out within the Iwatani Group

- 2. Eliminates issues of dimension-matching when molding

- 3. Offers high-precision insert-molded products

Major Applications

Automotive, office automation equipment, connectors

Facilities Owned

Resin molding machines: vertical rotary 100 t/150 t

Plants Involved

Company name: Zhongshan Kasatani Co., Ltd. Overview (Ownership: Iwatani 65%, Kasatani 35%)

1Advanced product processing using Japanese precision technologies

A production process encompassing sheet metal pressing and resin molding allows us to offer optimal configurations. Based on our motto—“A craftsman’s approach to creating new technologies”—we meet the advanced quality requirements of our customers, starting from mold design

2Reliable traceability and quality processing arrangements

We provide peace of mind to our customers through Japanese material controls as well as material procurement from a leading manufacturer with extensive experience.

3Diverse material procurement and cost competitiveness

Located within the site of Zhongshan Iwatani Co., Ltd., an industry-leading stainless steel and non-ferrous coil center. Control over the entire process, from material procurement and slitting to press processing, provides the benefits of diverse materials selection and high cost competitiveness.

Please inquire for more information.

Metals Department

Osaka

81-6-7637-3033

Tokyo

81-3-5405-5759

Services / Products

Resources & Advanced Materials Top

- Zr (Zirconium) Compounds

- Ti (Titanium) Compounds

- PKS (Palm Kernel Shells)

- Wood Pellet/Torrefied Wood Pellet

- Al (Aluminum) Compounds

- Mg (Magnesium) Compounds

- Phenolic Resins

- Carbon Black

- Fe (Ferrum)

- Rare Earth

- Se/Te (Selenium/Tellurium) Compounds

- Sr (Strontium) Compounds

- Si (Silicon) Compounds

- Ba (Barium) Compounds

- Co (Cobalt) Compounds

- Ta/Nb (Tantalum/Niobium) Compounds

- Ga (Gallium) Compounds

- W (Tungsten) Compounds

- Mo (Molybdenum) Compounds

- Li/Cs/Rb (Lithium/Cesium/Rubidium) Compounds

- Ni (Nickel)

- Epsilon Iron Oxide (Nanoparticles)

- Ceramic Shapes

- Ceramic Honeycomb

- Catalyst Carriers

- Urea

- Stainless Steel

- Aluminum

- Copper/Copper Alloys

- Surface Treated Steel Sheet

- Precision Stainless Steel

- Functional Aluminum Foil

- Hydrogen-Refueling Station Materials

- Clad Metal

- High Alloy Steels/Nickel Alloys

- Magnesium Alloys

- Highly Functional Stainless Steel Foil

- Non-magnetic Stainless Steel

- Beryllium Copper

- Titanium

- Wire Processed Products

- Display Furniture

- Carts

- Heat Treatment Jigs/Cleaning Jigs

- Metal Etching

- FRP (Fiber Reinforced Plastics) Tanks

- Precision/Ultra-Precision Slitting

- Precision Press Processing

- Insert-Molded Articles

- Nursing Care Products

- Secondary Metals

- Eyeglass Parts

- Cast-Iron Pipes

- CFRTP (Carbon Fiber Reinforced Thermoplastics)

- Bonded Dissimilar Materials

- Cu-Fe Alloys

- Medical Titanium Material

- Low-Carbon Aluminum

- Film Slitting Business

- High-Impact Absorbent Acrylic Foam ISR-ACF Series

- Thin Film Heat Dissipating Sheet

- Rework Foam Tape

- Silicone OCA for Foldables

- Silicone OCA for Vehicle Displays

- Optical Urethane Protective Film ISR-TSU Series

- Shock Absorption Sheets ISR-DP Series

- Electric Peeling Tape

- Ultrathin Adhesive Tape

- Low Environmental Impact Protective Film (Recycled Optical PET Protective Film)

- Differential Tape (AB Tape)

- Heavy Water/Deuterium Compounds

- Battery Internal Materials

- Cylindrical Battery Materials

- Square Battery Materials

- Pouch Battery Materials

- Electronic Component Materials

- Semiconductor/HDD Materials (High-Purity Metal, High Functional Packaging Materials)

- Moistureproof Materials/Antifoulants

- Subsidiary Materials for Batteries

- Fuel Cell Related