Materials / Electronic Materials

Pouch Battery Materials

Taper Processed Metals for Tab Leads and Acrylic Foam for EV Batteries

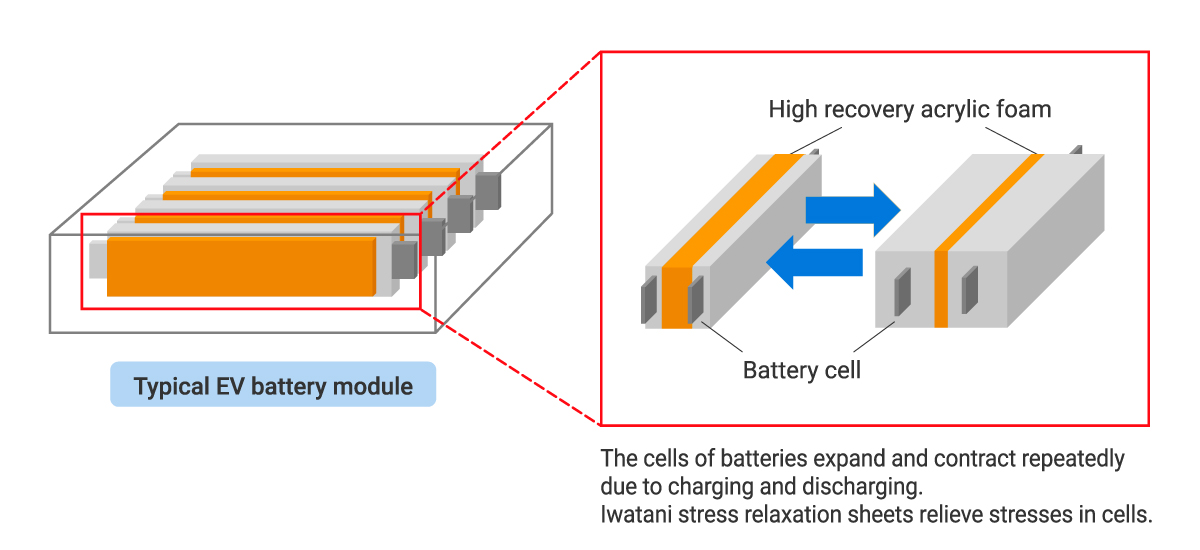

Pouch batteries offer low weight and greater latitude in form factors compared to square and cylindrical batteries. For these reasons, they are used widely in EV and mobile device applications. With our proprietary technologies and processing capabilities, we handle taper processed metals for tab leads and acrylic foam for EV batteries, and offer material development and processing solutions to meet customer requirements.

Product List

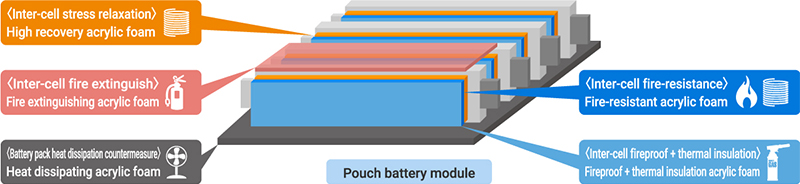

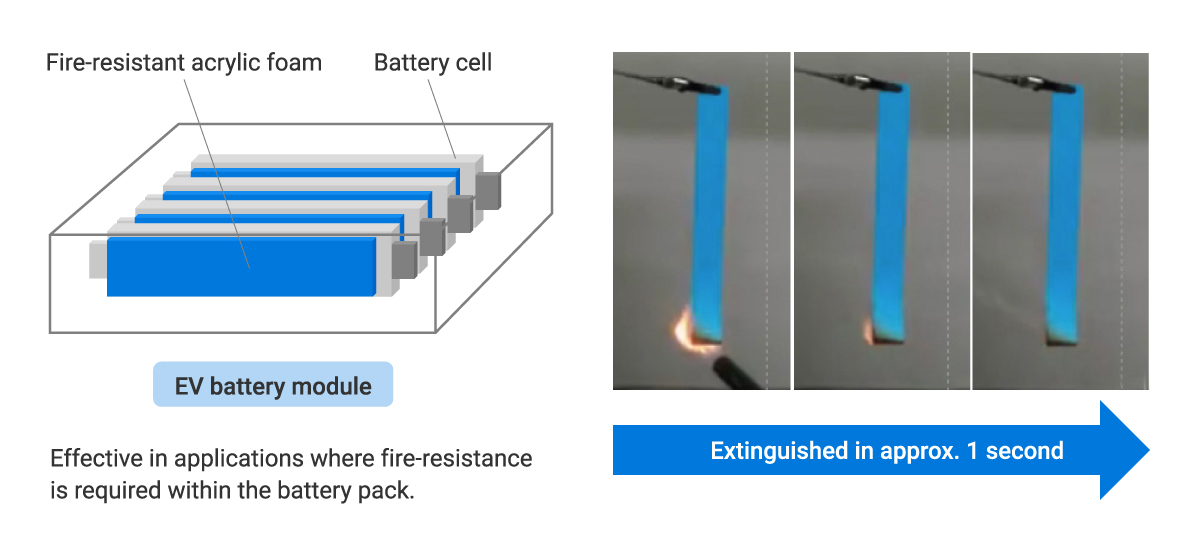

Acrylic Foam Series for EV Batteries

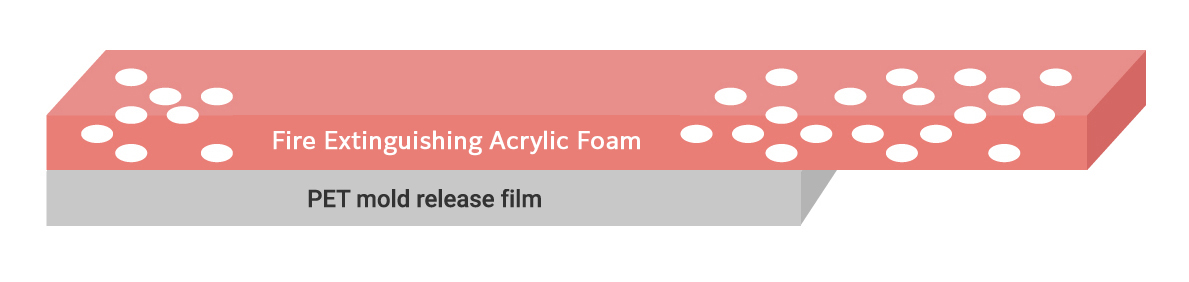

Fire Extinguishing Acrylic Foam

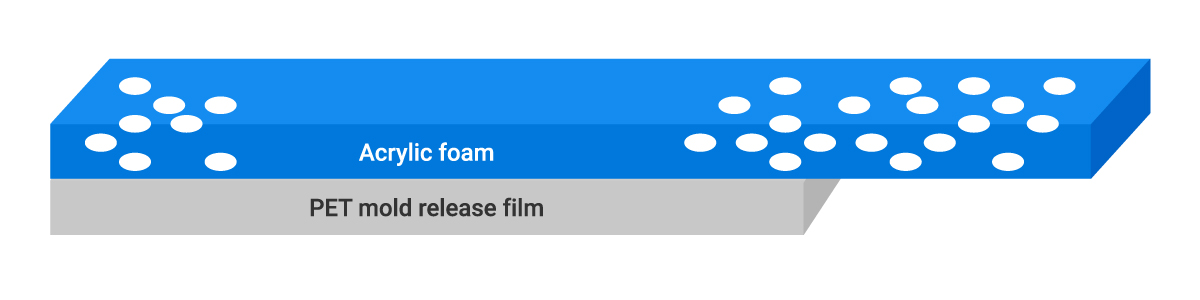

Construction

Applications

- Inside battery pack and module for EV

- Parts with risk of ignition

- Due to the soft sheet, this material can be attached to various locations

Characteristics

| Item | Units | Developed products |

|---|---|---|

| Thickness | mm | 1.8 |

| Density | g/cm3 | 0.73 |

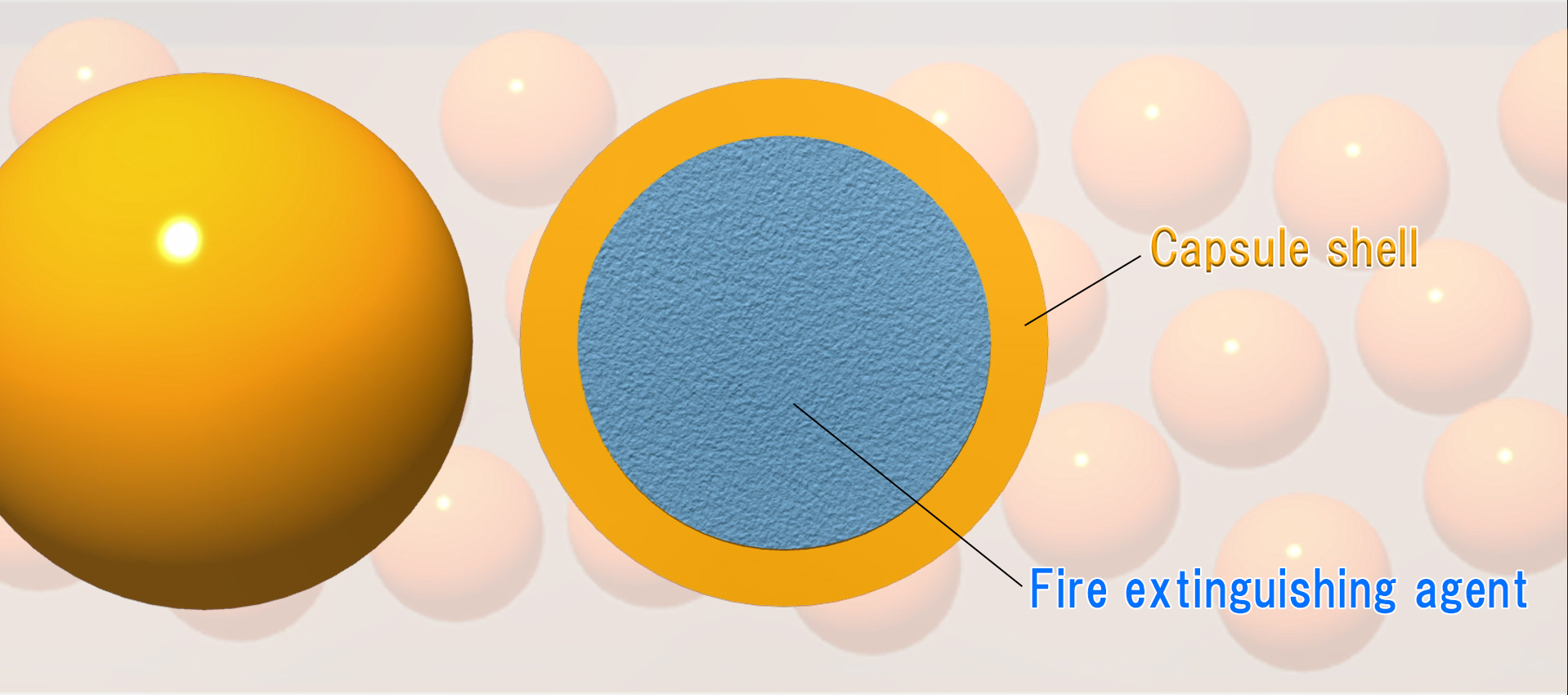

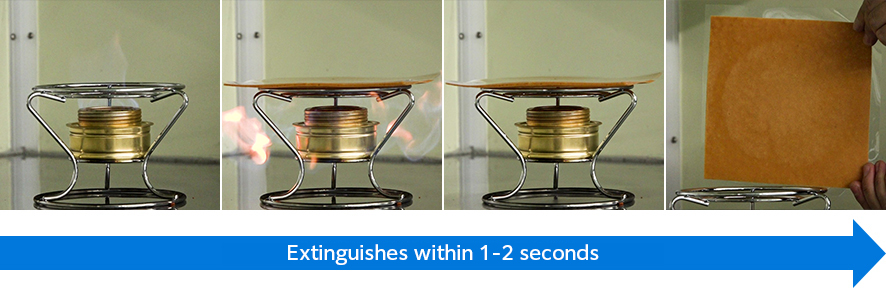

Fire Extinguishing Mechanism

Fire extinguishing performance test with gas torch

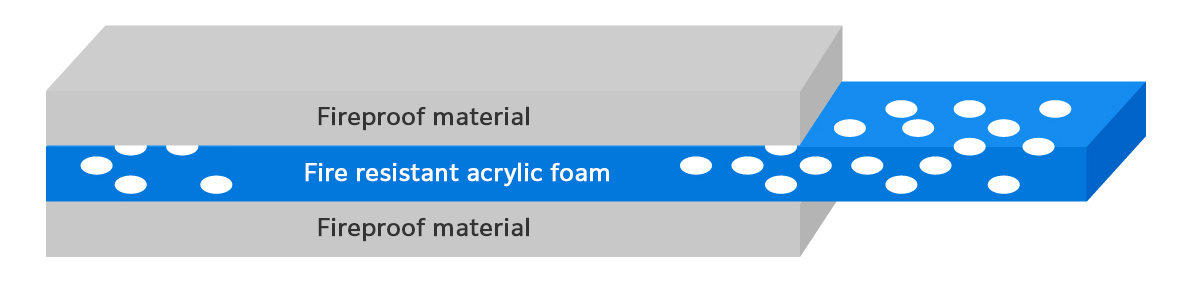

Fireproof + Thermal Insulation Acrylic Foam

Construction

Applications

- Between the cells of EV batteries

- Applications requiring fireproof and thermal insulation

Characteristics

- 1. Adds fireproof and thermal Insulation to conventional flame retardant foam.

- 2. Even if you apply a gas torch to the product, the fire will not penetrate and break through the product.

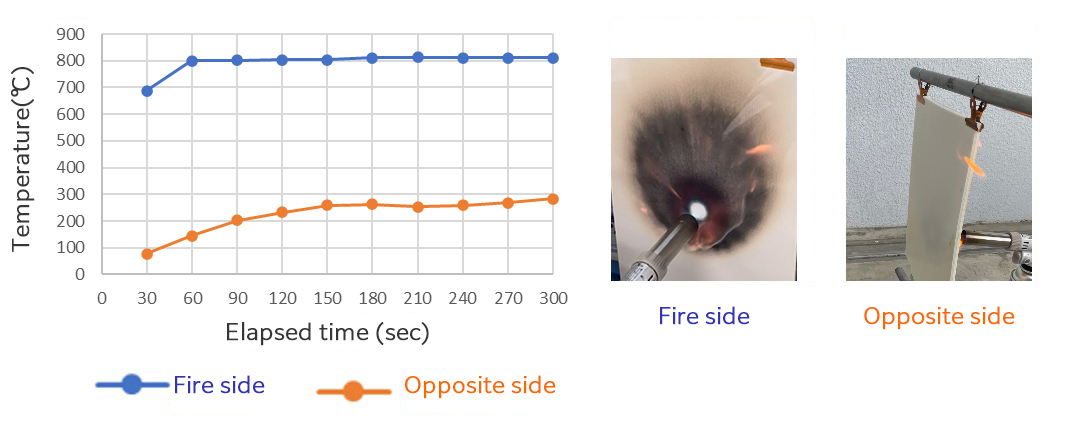

- 3. Due to its High Thermal insulation, the unheated surface stays below 300℃ even when heated to 800℃. (Within 300 seconds)

- 4. Cushion foam made from acrylic material with high shock absorption.

Insulation test with a total thickness of about 3.5 mm

| Temperature measurement surface | Elapsed time (sec) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 60 | 90 | 120 | 150 | 180 | 210 | 240 | 270 | 300 | |

| Fire side(℃) | 687 | 800 | 802 | 803 | 804 | 811 | 812 | 811 | 812 | 812 |

| Opposite side(℃) | 77 | 144 | 203 | 233 | 259 | 263 | 253 | 259 | 268 | 283 |

| Thermal Insulation effect(℃) | -610 | -656 | -599 | -570 | -545 | -548 | -559 | -552 | -544 | -529 |

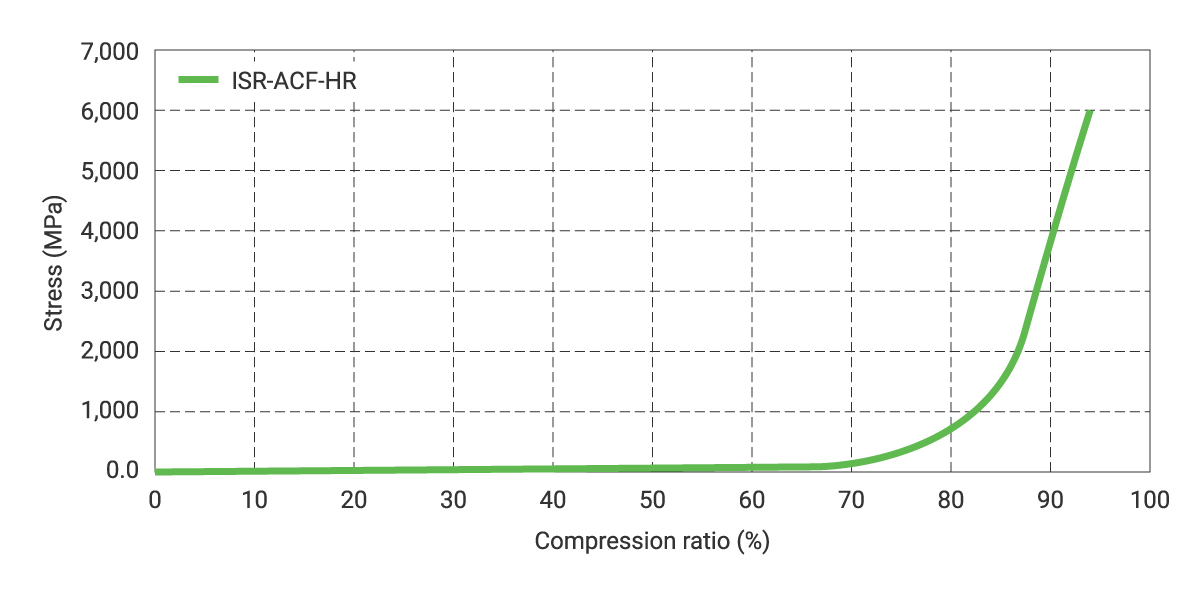

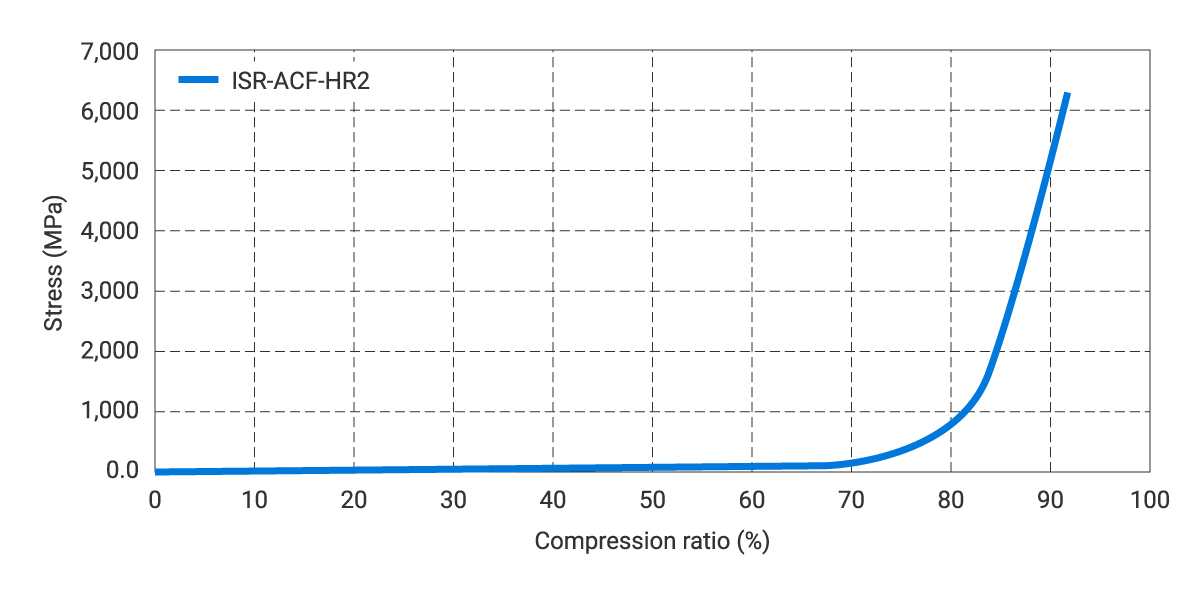

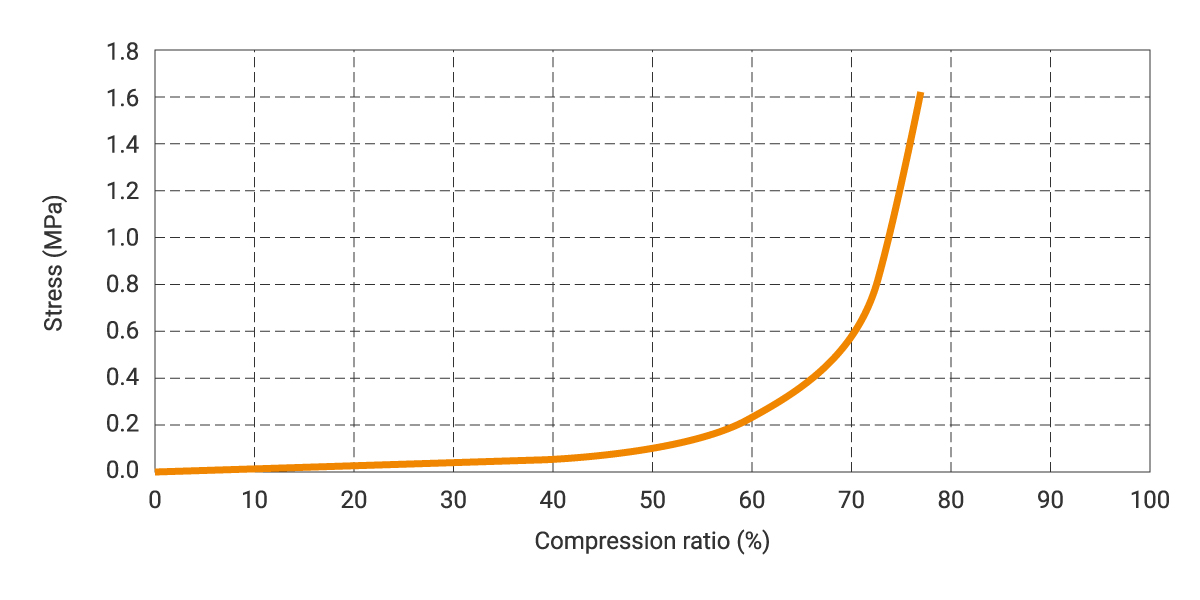

High Recovery Acrylic Foam (Compression Pads)

Construction

Applications

Characteristics

| Item | Units | ISR-ACF-HR | ISR-ACF-HR2 | |

|---|---|---|---|---|

| Thickness | mm | 0.5 to 3.0 | ||

| Density | g/cm3 | 0.3 to 0.35 | ||

| Adsorption force on SUS |

N/25 mm | Surface | 0.87 | 0.22 |

| PET separator surface | N/25 mm | 2.00 | 1.72 | |

| Compression set 70% compression × 70°C × 22 hrs |

% | 4.03 | 2.79 | |

| Long-term compression set 70% compression × 55°C × 50%RH × 1,000 hrs |

% | 20.76 | 13.42 | |

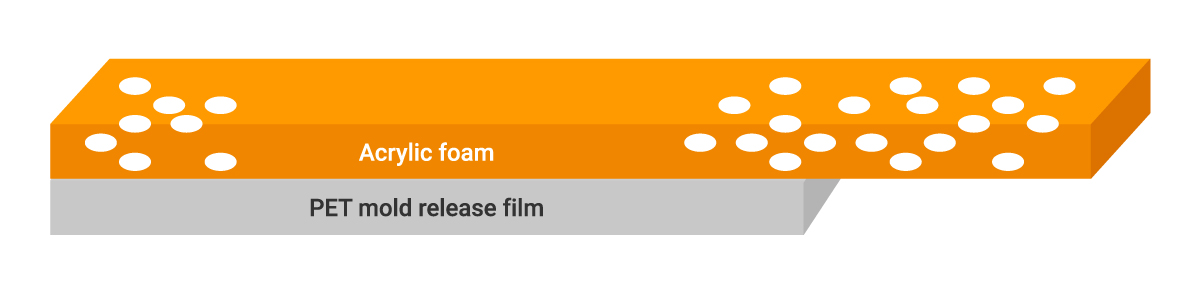

Fire-Resistant Acrylic Foam

Construction

Applications

Characteristics

| Item | Units | ISR-ACF-FR | |

|---|---|---|---|

| Thickness | mm | 1.0 to 3.0 | |

| Density | g/cm3 | 0.35 | |

| Adsorption force on SUS |

Surface | N/25 mm | 0.03 |

| PET separator surface | N/25 mm | 0.85 | |

| Compression set 50% compression × normal temperature × 72 hrs |

% | 35.02 | |

| Compression set 50% compression × 70°C temperature × 22 hrs |

% | 45.96 | |

| Surface resistivity | Ω | 1011 < | |

| Thermal conductivity | Thickness direction | W/m·K | 0.121 |

| Within the surface plane | W/m·K | 0.249 | |

| UL94 V-0 test | - | Pass | |

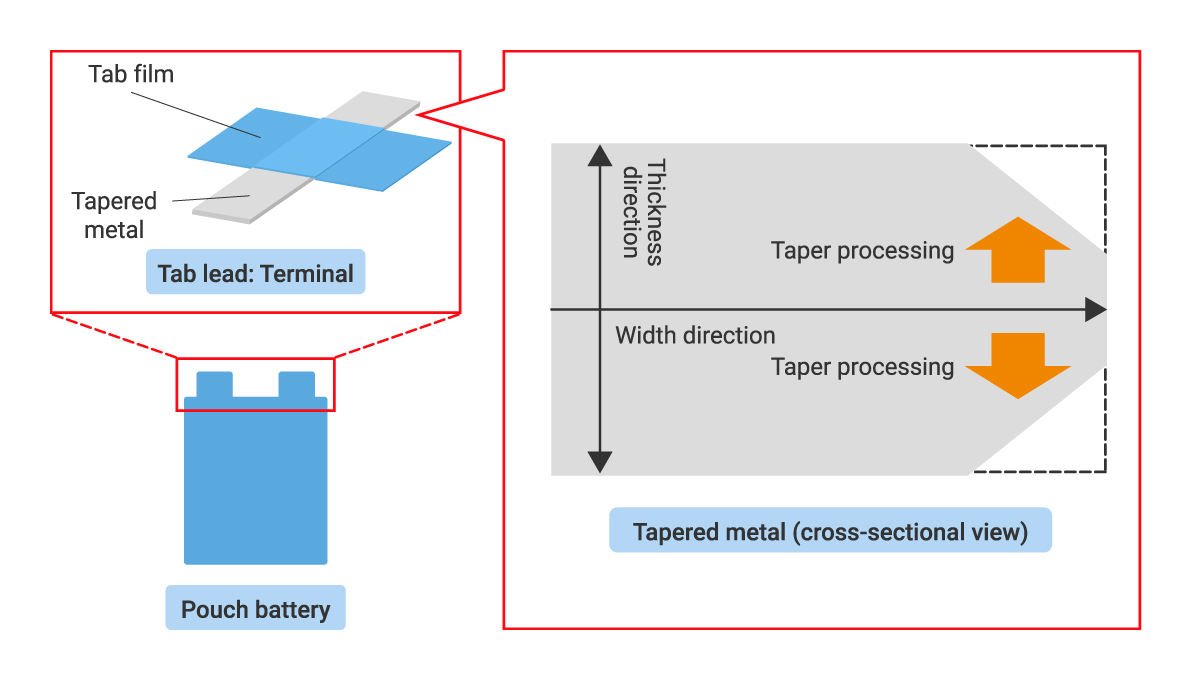

Taper Processed Metals for Tab Leads

| Products available | Applications | Characteristics |

|---|---|---|

| Tapered aluminum | Tab lead for cathode | The metal foil is tapered to improve tab film sealing characteristics. We can also tailor shapes to meet customer requirements. |

| Tapered copper | Tab lead for anode |

Please inquire for more information.

Electronic Materials Department

Services / Products

Resources & Advanced Materials Top

- Zr (Zirconium) Compounds

- Ti (Titanium) Compounds

- PKS (Palm Kernel Shells)

- Wood Pellet/Torrefied Wood Pellet

- Al (Aluminum) Compounds

- Mg (Magnesium) Compounds

- Phenolic Resins

- Carbon Black

- Fe (Ferrum)

- Rare Earth

- Se/Te (Selenium/Tellurium) Compounds

- Sr (Strontium) Compounds

- Si (Silicon) Compounds

- Ba (Barium) Compounds

- Co (Cobalt) Compounds

- Ta/Nb (Tantalum/Niobium) Compounds

- Ga (Gallium) Compounds

- W (Tungsten) Compounds

- Mo (Molybdenum) Compounds

- Li/Cs/Rb (Lithium/Cesium/Rubidium) Compounds

- Ni (Nickel)

- Epsilon Iron Oxide (Nanoparticles)

- Ceramic Shapes

- Ceramic Honeycomb

- Catalyst Carriers

- Urea

- Stainless Steel

- Aluminum

- Copper/Copper Alloys

- Surface Treated Steel Sheet

- Precision Stainless Steel

- Functional Aluminum Foil

- Hydrogen-Refueling Station Materials

- Clad Metal

- High Alloy Steels/Nickel Alloys

- Magnesium Alloys

- Highly Functional Stainless Steel Foil

- Non-magnetic Stainless Steel

- Beryllium Copper

- Titanium

- Wire Processed Products

- Display Furniture

- Carts

- Heat Treatment Jigs/Cleaning Jigs

- Metal Etching

- FRP (Fiber Reinforced Plastics) Tanks

- Precision/Ultra-Precision Slitting

- Precision Press Processing

- Insert-Molded Articles

- Nursing Care Products

- Secondary Metals

- Eyeglass Parts

- Cast-Iron Pipes

- CFRTP (Carbon Fiber Reinforced Thermoplastics)

- Bonded Dissimilar Materials

- Cu-Fe Alloys

- Medical Titanium Material

- Low-Carbon Aluminum

- Film Slitting Business

- High-Impact Absorbent Acrylic Foam ISR-ACF Series

- Thin Film Heat Dissipating Sheet

- Rework Foam Tape

- Silicone OCA for Foldables

- Silicone OCA for Vehicle Displays

- Optical Urethane Protective Film ISR-TSU Series

- Shock Absorption Sheets ISR-DP Series

- Electric Peeling Tape

- Ultrathin Adhesive Tape

- Low Environmental Impact Protective Film (Recycled Optical PET Protective Film)

- Differential Tape (AB Tape)

- Heavy Water/Deuterium Compounds

- Battery Internal Materials

- Cylindrical Battery Materials

- Square Battery Materials

- Pouch Battery Materials

- Electronic Component Materials

- Semiconductor/HDD Materials (High-Purity Metal, High Functional Packaging Materials)

- Moistureproof Materials/Antifoulants

- Subsidiary Materials for Batteries

- Fuel Cell Related