Materials / Metals

Bonded Dissimilar Materials

Applying dissimilar material bonding technologies to promote use of multi-materials

Bonding dissimilar metals and bonding metals to resins can increase added value by boosting performance and functionality. It can also reduce costs by allowing the substitution of lower grade materials. Iwatani bonds a wide range of different materials to offer solutions to a range of needs.

Product Details

Bonded Materials

| Materials | Configuration |

|---|---|

| Metal + metal (identical/dissimilar alloys) Metal + metal (dissimilar metals) Metal + resin Metal + composite (CFRP/GFRP) |

Sheet, bar, pipe, processed product |

Description of Technology

Iwatani offers bonding technology optimized for the materials and configurations being bonded. *This is just one example of the bonding technologies we offer.

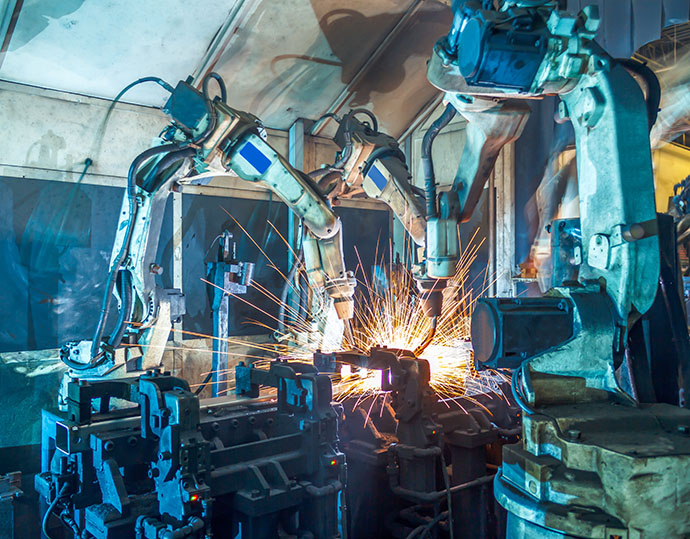

Fusing (Arc/Electron Beam/Laser Welding)

Fusing is the most common welding technique. Fusing involves fusing the parent material and filler or just one of the two. Iwatani not only offers technological solutions, but also provides a comprehensive range of welding methods, welding materials, gas, and equipment.

Pressure Welding (FSW/Ultrasonic Welding/Diffusion Bonding)

Pressure welding refers to joining processes in which components are joined by applying pressure and heat, the latter generated by explosive energy or friction. This offers great latitude in materials and dimensions and requires no additional welding materials. This makes it ideal for bonding dissimilar materials.

Chemical/Mechanical Bonding

This is a new technology for bonding metals and resins without adhesives. Modifying the metal surface makes it possible to achieve strong bonds via chemical and mechanical bonding between metals and resins.

Please inquire for more information.

Metals Department

Osaka

81-6-7637-3033

Tokyo

81-3-5405-5759

Services / Products

Resources & Advanced Materials Top

- Zr (Zirconium) Compounds

- Ti (Titanium) Compounds

- PKS (Palm Kernel Shells)

- Wood Pellet/Torrefied Wood Pellet

- Al (Aluminum) Compounds

- Mg (Magnesium) Compounds

- Phenolic Resins

- Carbon Black

- Fe (Ferrum)

- Rare Earth

- Se/Te (Selenium/Tellurium) Compounds

- Sr (Strontium) Compounds

- Si (Silicon) Compounds

- Ba (Barium) Compounds

- Co (Cobalt) Compounds

- Ta/Nb (Tantalum/Niobium) Compounds

- Ga (Gallium) Compounds

- W (Tungsten) Compounds

- Mo (Molybdenum) Compounds

- Li/Cs/Rb (Lithium/Cesium/Rubidium) Compounds

- Ni (Nickel)

- Epsilon Iron Oxide (Nanoparticles)

- Ceramic Shapes

- Ceramic Honeycomb

- Catalyst Carriers

- Urea

- Stainless Steel

- Aluminum

- Copper/Copper Alloys

- Surface Treated Steel Sheet

- Precision Stainless Steel

- Functional Aluminum Foil

- Hydrogen-Refueling Station Materials

- Clad Metal

- High Alloy Steels/Nickel Alloys

- Magnesium Alloys

- Highly Functional Stainless Steel Foil

- Non-magnetic Stainless Steel

- Beryllium Copper

- Titanium

- Wire Processed Products

- Display Furniture

- Carts

- Heat Treatment Jigs/Cleaning Jigs

- Metal Etching

- FRP (Fiber Reinforced Plastics) Tanks

- Precision/Ultra-Precision Slitting

- Precision Press Processing

- Insert-Molded Articles

- Nursing Care Products

- Secondary Metals

- Eyeglass Parts

- Cast-Iron Pipes

- CFRTP (Carbon Fiber Reinforced Thermoplastics)

- Bonded Dissimilar Materials

- Cu-Fe Alloys

- Medical Titanium Material

- Low-Carbon Aluminum

- Film Slitting Business

- High-Impact Absorbent Acrylic Foam ISR-ACF Series

- Thin Film Heat Dissipating Sheet

- Rework Foam Tape

- Silicone OCA for Foldables

- Silicone OCA for Vehicle Displays

- Optical Urethane Protective Film ISR-TSU Series

- Shock Absorption Sheets ISR-DP Series

- Electric Peeling Tape

- Ultrathin Adhesive Tape

- Low Environmental Impact Protective Film (Recycled Optical PET Protective Film)

- Differential Tape (AB Tape)

- Heavy Water/Deuterium Compounds

- Battery Internal Materials

- Cylindrical Battery Materials

- Square Battery Materials

- Pouch Battery Materials

- Electronic Component Materials

- Semiconductor/HDD Materials (High-Purity Metal, High Functional Packaging Materials)

- Moistureproof Materials/Antifoulants

- Subsidiary Materials for Batteries

- Fuel Cell Related