Materials / Metals

Metal Etching

Meeting Requirements for High Accuracy, Low Cost, and Short Lead Times

Iwatani offers high-quality, high-accuracy components based on precision etching of stainless steel and nickel foils. Products can be etched on both sides, one side, or half-etched to suit particular requirements and applications.

Features

- 1. Allows forming of complex shapes not possible with stamping

- 2. Allows forming free of distortion and burrs

- 3. Eliminates the need for molds, reducing initial costs

- 4. Production and/or supply outside Japan possible, improving cost competitiveness

Product Details

Available Specifications

| Processing Size | Minimum sheet thickness 0.01 mm, width 1,000 mm * Varies by material. |

|---|---|

| Supplied Format | Roll supply, sheet supply |

| Metal Materials | SUS-CSP foil (e.g., 304, 301, 316L, non-magnetic SUS, TA treated material) |

| Copper based (e.g., oxygen-free copper, tough pitch copper, beryllium copper, high-strength copper alloy) | |

| Nickel alloy (e.g., 42 alloy, pure nickel, Permalloy, Inconel) | |

| High performance materials (e.g., titanium, nickel silver, tungsten, precious metals) | |

| Etching Type | Double-sided etching, single-sided etching, half etching |

| Secondary Processing | Bending, corrosion proofing, coating, resin forming, etc. |

- *Specifications such as base material size, dimensional tolerances, and pitch tolerances vary depending on the material. Please inquire for more information.

- *Processing is also possible for materials provided by the customer.

Typical Applications

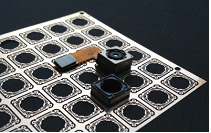

● VCM spring for camera module

Base material: High-strength copper alloy, non-magnetic SUS foil

*Additionally. electrostatic grids and static eliminators for printers, organic EL metal masks, shield plates for camera modules, metal filters, metal masks for silicon wafers, etc.

Please inquire for more information.

Metals Department

Osaka

81-6-7637-3033

Tokyo

81-3-5405-5759

Services / Products

Resources & Advanced Materials Top

- Zr (Zirconium) Compounds

- Ti (Titanium) Compounds

- PKS (Palm Kernel Shells)

- Wood Pellet/Torrefied Wood Pellet

- Al (Aluminum) Compounds

- Mg (Magnesium) Compounds

- Phenolic Resins

- Carbon Black

- Fe (Ferrum)

- Rare Earth

- Se/Te (Selenium/Tellurium) Compounds

- Sr (Strontium) Compounds

- Si (Silicon) Compounds

- Ba (Barium) Compounds

- Co (Cobalt) Compounds

- Ta/Nb (Tantalum/Niobium) Compounds

- Ga (Gallium) Compounds

- W (Tungsten) Compounds

- Mo (Molybdenum) Compounds

- Li/Cs/Rb (Lithium/Cesium/Rubidium) Compounds

- Ni (Nickel)

- Epsilon Iron Oxide (Nanoparticles)

- Ceramic Shapes

- Ceramic Honeycomb

- Catalyst Carriers

- Urea

- Stainless Steel

- Aluminum

- Copper/Copper Alloys

- Surface Treated Steel Sheet

- Precision Stainless Steel

- Functional Aluminum Foil

- Hydrogen-Refueling Station Materials

- Clad Metal

- High Alloy Steels/Nickel Alloys

- Magnesium Alloys

- Highly Functional Stainless Steel Foil

- Non-magnetic Stainless Steel

- Beryllium Copper

- Titanium

- Wire Processed Products

- Display Furniture

- Carts

- Heat Treatment Jigs/Cleaning Jigs

- Metal Etching

- FRP (Fiber Reinforced Plastics) Tanks

- Precision/Ultra-Precision Slitting

- Precision Press Processing

- Insert-Molded Articles

- Nursing Care Products

- Secondary Metals

- Eyeglass Parts

- Cast-Iron Pipes

- CFRTP (Carbon Fiber Reinforced Thermoplastics)

- Bonded Dissimilar Materials

- Cu-Fe Alloys

- Medical Titanium Material

- Low-Carbon Aluminum

- Film Slitting Business

- High-Impact Absorbent Acrylic Foam ISR-ACF Series

- Thin Film Heat Dissipating Sheet

- Rework Foam Tape

- Silicone OCA for Foldables

- Silicone OCA for Vehicle Displays

- Optical Urethane Protective Film ISR-TSU Series

- Shock Absorption Sheets ISR-DP Series

- Electric Peeling Tape

- Ultrathin Adhesive Tape

- Low Environmental Impact Protective Film (Recycled Optical PET Protective Film)

- Differential Tape (AB Tape)

- Heavy Water/Deuterium Compounds

- Battery Internal Materials

- Cylindrical Battery Materials

- Square Battery Materials

- Pouch Battery Materials

- Electronic Component Materials

- Semiconductor/HDD Materials (High-Purity Metal, High Functional Packaging Materials)

- Moistureproof Materials/Antifoulants

- Subsidiary Materials for Batteries

- Fuel Cell Related