Materials / Metals

Precision Stainless Steel

An Essential Material for Next Generation Technologies

Precision stainless steel refers to stainless steel with a strength of at least HV530 and functional stainless steels such as ultrathin stainless steel measuring 15 µm or 20 µm thick. Expanding high speed, high capacity communications and next generation vehicles are driving use of this steel for electronic devices, mobile equipment, and vehicles. Iwatani operates a precision slitting business and has established a system for supplying customers around the world.

Product Details

Product Characteristics

1Stainless Steel for Springs

Offers increased hardness and tensile strength compared to conventional stainless steel. Mechanical properties can be tuned through rolling.

- SUS301: Austenitic stainless steel; harder and stronger than SUS304

- SUS304: The most commonly used stainless steel; greater corrosion resistance than SUS301

- SUS631: Steel subjected to precipitation hardening for increased hardness

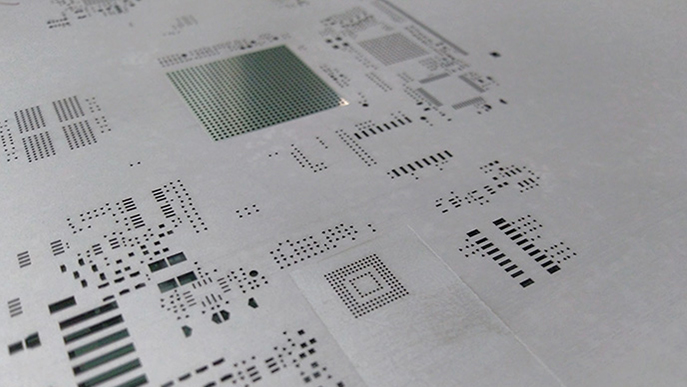

2Stainless Steel for Etching

Stainless steel can be supplied with flatness increased by tension annealing (TA) for use in etching and other applications that require high flatness.

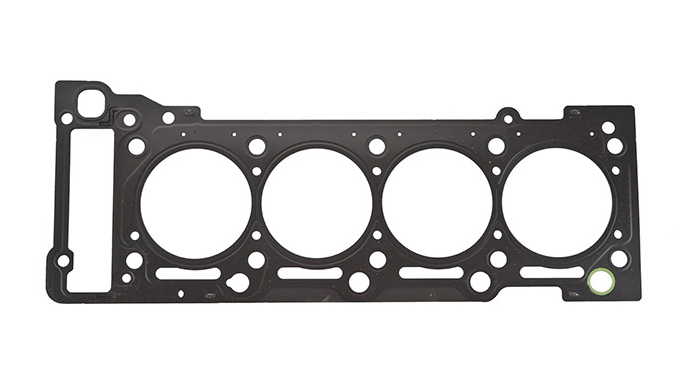

3Stainless Steel for Gaskets

Features a finer crystalline structure to achieve high spring performance and fatigue characteristics.

4Stainless Steel for Automotive Molding

Provides a superior sheen for ferritic steel; used in vehicle door moldings. We offer a wide range of designs featuring color processing and coatings.

Major Applications

- Automotive components (e.g., metal gaskets, door moldings)

- Battery components (e.g., casings, current collectors, separators)

- Electronic components (e.g., dome switches, smartphone chassis, motor components)

- Precision processed components (e.g., etching base metal, metals masks)

- Camera components (e.g., VCM modules)

- Office automation equipment (e.g., toner blades)

- Medical equipment (e.g., hemoclips)

● Metal gaskets

● Metal masks

Processing Sites

Suzhou Iwatani Metal Products Co., Ltd. and Zhongshan Iwatani Co., Ltd. are Iwatani group companies responsible for precision slitting of precision stainless steel and non-ferrous metal materials. They make possible a wide range of lighter and thinner metal materials for electronics sector applications that demand more compact dimensions, lower weight, resource savings, energy savings, and increased capacity. These companies supply materials for a wide range of domestic applications within China, including rechargeable batteries, liquid crystal, organic EL, smartphones, connectors, and office equipment.

Please inquire for more information.

Metals Department

Osaka

81-6-7637-3033

Tokyo

81-3-5405-5759

Services / Products

Resources & Advanced Materials Top

- Zr (Zirconium) Compounds

- Ti (Titanium) Compounds

- PKS (Palm Kernel Shells)

- Wood Pellet/Torrefied Wood Pellet

- Al (Aluminum) Compounds

- Mg (Magnesium) Compounds

- Phenolic Resins

- Carbon Black

- Fe (Ferrum)

- Rare Earth

- Se/Te (Selenium/Tellurium) Compounds

- Sr (Strontium) Compounds

- Si (Silicon) Compounds

- Ba (Barium) Compounds

- Co (Cobalt) Compounds

- Ta/Nb (Tantalum/Niobium) Compounds

- Ga (Gallium) Compounds

- W (Tungsten) Compounds

- Mo (Molybdenum) Compounds

- Li/Cs/Rb (Lithium/Cesium/Rubidium) Compounds

- Ni (Nickel)

- Epsilon Iron Oxide (Nanoparticles)

- Ceramic Shapes

- Ceramic Honeycomb

- Catalyst Carriers

- Urea

- Stainless Steel

- Aluminum

- Copper/Copper Alloys

- Surface Treated Steel Sheet

- Precision Stainless Steel

- Functional Aluminum Foil

- Hydrogen-Refueling Station Materials

- Clad Metal

- High Alloy Steels/Nickel Alloys

- Magnesium Alloys

- Highly Functional Stainless Steel Foil

- Non-magnetic Stainless Steel

- Beryllium Copper

- Titanium

- Wire Processed Products

- Display Furniture

- Carts

- Heat Treatment Jigs/Cleaning Jigs

- Metal Etching

- FRP (Fiber Reinforced Plastics) Tanks

- Precision/Ultra-Precision Slitting

- Precision Press Processing

- Insert-Molded Articles

- Nursing Care Products

- Secondary Metals

- Eyeglass Parts

- Cast-Iron Pipes

- CFRTP (Carbon Fiber Reinforced Thermoplastics)

- Bonded Dissimilar Materials

- Cu-Fe Alloys

- Medical Titanium Material

- Low-Carbon Aluminum

- Film Slitting Business

- High-Impact Absorbent Acrylic Foam ISR-ACF Series

- Thin Film Heat Dissipating Sheet

- Rework Foam Tape

- Silicone OCA for Foldables

- Silicone OCA for Vehicle Displays

- Optical Urethane Protective Film ISR-TSU Series

- Shock Absorption Sheets ISR-DP Series

- Electric Peeling Tape

- Ultrathin Adhesive Tape

- Low Environmental Impact Protective Film (Recycled Optical PET Protective Film)

- Differential Tape (AB Tape)

- Heavy Water/Deuterium Compounds

- Battery Internal Materials

- Cylindrical Battery Materials

- Square Battery Materials

- Pouch Battery Materials

- Electronic Component Materials

- Semiconductor/HDD Materials (High-Purity Metal, High Functional Packaging Materials)

- Moistureproof Materials/Antifoulants

- Subsidiary Materials for Batteries

- Fuel Cell Related