Machinery / Semiconductors and Automation

Wire Bonders/Ball Bonders

Iwatani offers advanced one-stop solutions that encompass all processes encountered in the semiconductor manufacturing sector.

Thermosonic Ball Bonder (Au, Cu, Ag)

Industry-Leading Bonding Speed: 43 Msec/Wire Ideal for Manufacturing Led and Discrete Products

We offer the capabilities needed to respond to the advanced and diverse semiconductor manufacturing assembly process requirements of our customers, including high speed, high precision, diverse low-volume production, cost effectiveness, and stability. The fully automatic wire bonder features dual-frequency ultrasonic waves as standard to support a wide range of products, a bonding time of 0.043 seconds per wire for high-speed productivity-boosting performance, and advanced temperature compensation technology to achieve a bonding accuracy of 3σ ≤2.0 μm.

Features

- High productivity

- Supported frame sizes increased to max. L 300 mm × W 90 mm

- Supports Au wire of diameters ranging from 12 to 75 μm for stable FAB formation

- Low-capacitance non-bonding detection function

- High-capacity 64 GB SSD

- Traceability functions for managing production information via USB memory stick or LAN

- SECS/GEM provided as standard

- Compatible with the manufacturer’s own host management system

- Windows 10 OS

Specifications

| Bonding Performance | Bonding accuracy | ±2.5 μm (3σ) |

|---|---|---|

| Bonding area | 56 mm × 80 mm | |

| Productivity | Bonding time | 43 msec/wire |

| Transport System | Package frame size |

|

| Magazine |

|

|

| Other | Exterior dimensions |

|

| Weight | 550 kg |

Thermosonic Ball Bonder (Au, Cu, Ag)

Wide Area Bonder, Which Also Handles Large IC Devices

With a vertical bonding area of up to 95 mim and frame width of up to 105 mm, This model accommodates large IC devices.

Features

- Supported frame sizes increased to max. L 300 mm × W 105 mm

- Supports Au wire of diameters ranging from 12 to 75 μm for stable FAB formation.

- Low-capacitance non-bonding detection function

- High-capacity 64 GB SSD

- Traceability functions for managing production information via USB memory stick or LAN

- SECS/GEM provided as standard

- Compatible with the manufacturer's own host management system

- Windows 10 OS

Specifications

| Bonding Performance | Bonding accuracy (excluding self-teaching accuracy) |

±3.0 μm (3σ) *Requires special kit for accuracy stability. |

|---|---|---|

| Bonding area | 56 mm × 95 mm | |

| Productivity | Bonding time | 50 msec/wire |

| Supported Transport System | Package frame size |

|

| Magazine |

|

|

| Other | Exterior dimensions |

|

| Weight | 550 kg |

Wafer Level Bump Bonder

Bump Bonder for Wafers of up to 8 Inches

The fully automatic wafer level bonder has excellent operability due to the easy product-type programming function.

Features

- Four to six inch wafer (carrier transport)

- Four to eight inch wafer (manual mounting specification; automatic transport is available as option)

- Equipped with a small oscillator that minimizes the effects of radiant heat

- Supports low temperature bonding

- Real-time position accuracy correction

- Step bond sequence

- SECS/GEM provided as standard

- Traceability functions for managing production information via USB memory stick or LAN

- Windows 10 OS

Specifications

| Bonding Performance | Bonding accuracy | ±3.0 μm (3σ) |

|---|---|---|

| Bonding area | 56 mm × 95 mm | |

| Productivity | Bonding time | 30 msec/bump (pill-cut mode) |

| 40 msec/bump (fix-cut mode) | ||

| Supported Transport System (Carrier Transport) | Wafer size | Up to 6 inches |

| Transport method | Automatic transfer by using carrier tape | |

| Magazine |

|

|

| Other | Exterior dimensions |

|

Wire Bonders for Laser (Rotatable Bonding Stage)

Supports TO-Can for Laser Products, COC/COS Transport and Rotary Bonding

The COC/COS wire bonder for laser products and the TO-Can single-piece transfer method are used to support + 90/-90 degree rotary bonding. Products (COC/COS) can be supplied with Gel packs or Waffle packs.

Features

- + 90/-90 degree (180 angle range) rotation bonding

- Dual-frequency ultrasonic transducer

- Transport tray setting with separate supply and storage

- Multi-step recognition focus setting

- Easy product switching between TO-Can products and COC/COS products

Specifications

| Bonding Performance (Excluding Self-Teaching Accuracy) | Bonding accuracy | ±2.5 μm (3σ) (excluding self-teaching accuracy) |

|---|---|---|

| Bonding area | 15 mm × 80 mm | |

| Productivity | Bonding time | 43 msec/wire (2 mm long wire) |

| Supported Transport System | Product dimensions |

|

| Waffle pack size | 2 to 4 inches | |

| Gel pack size | 2 to 4 inches | |

| Other | Exterior dimensions |

|

| Weight | 550 kg |

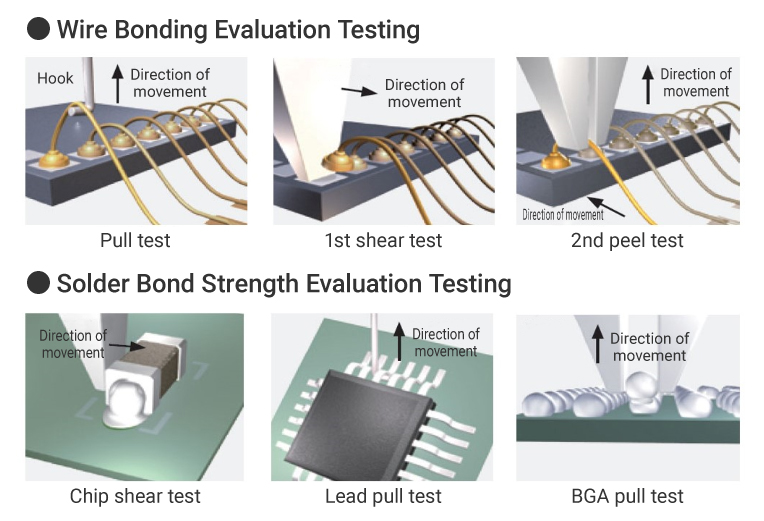

Bonding Tester

From Next Generation Mounting R&D to Quality Control Semiconductor Post-Processing Bond Strength Evaluation Using a Single Unit

Features load detection accuracy and fine adjustment accuracy for measuring gold wire pull (tensile) strength and ball shear strength. Switches sensors to maintain accuracy in low-load regions, even in high-load region measurements, including measurements of die shear strength and solder bond strength.

Features

- Capable of evaluating Au, Al, Cu, and ball, wedge, ribbon, and die bonding.

- The measuring direction and speed is kept constant using three-axis drive control to ensure that consistent results can be obtained by anyone easily.

- Numerical evaluations based on test methods that meet Japanese and international requirements and standards

- ● JIS Z 3198-6/7

- ● MIL-STD-883

- ● JEITA ED 7403/7407

- ● IEC 749

- ● JEITA ED 4703

- ● SEMI G73-0997

Measurement Examples

Specifications

| Measured Load Range | Pull test Push test Peel test |

Max. 20 kg |

|---|---|---|

| Shear test | Max. 100 kg | |

| Measurement Accuracy | ±0.2%FS | |

| Measurement Speed Range | Pull test Push test Peel test |

0.001 to 5 mm/s |

| Shear test | 0.001 to 10 mm/s | |

| Drive Range | X axis | ±50 mm |

| Y axis | ± 50 mm | |

| Z axis | Max. 70 mm | |

| Observation Direction | Vertically | 45° |

| Horizontally | ±90° control |

3D Wire Visual Inspection System

Visual Inspection System That Achieves the Inspection Automation and Efficiency Required in the Wire Bonding Process

Features

-

High Performance 3D Measurement

Equipped with a 3D measurement function based on the in-focus method. Compared to other 3D measurement methods, it excels in measuring inclined surfaces and fine structures to enable visual inspections with fewer false positives. -

High Reliability Inspection by Dimensional Measurement

Allows measurement of some 20 types of dimensions such as wire maximum height and bond width. A standard range can be set for the dimensions of each location; if this value deviates from the standard range, the system can be set to reject the product. -

Traceability Support

A traceability environment can be built based on reading 2D codes marked on workpieces and sending this information to the server together with inspection results. Analyzing each measurement result makes it possible to grasp assembly variations and tendencies to improve upstream processes. -

Ease of Use

For inspections, simply select the name of the product to inspect and start the inspection. The loader/unloader enables automatic workpiece supply/discharge.

Please inquire for more information on wire bonders and ball bonders.

Electronics Equipment Department

Tokyo

81-3-5405-5781

Osaka

81-6-7637-3072