Machinery / Semiconductors and Automation

Die Bonders

Iwatani offers advanced one-stop solutions that encompass all processes encountered in the semiconductor manufacturing sector.

Soft Solder Die Bonder (8-Inch)

Die Bonder for Solder Bonding Processes for Power Devices Requiring High Quality Bonding

Features

- Incorporates high performance reduction feeder for solder fusing bonding.

- Incorporates solder spanker (forming) function for high bonding quality.

- Supports large frames up to 100 mm wide.

- Provides flexible support for wafer mapping and traceability.

- Supports wafer sizes up to 8-inch diameter

Specifications

| Bonding Method | Wire solder feed bonding |

|---|---|

| Bonding Speed UPH | 6,000 (with SOP8 continuous matrix frame and chip size equivalent to 3-mm square) |

| Bonding Accuracy (Using CU Island, Spanker, and Pyramidal Collet) | XY: ±38 µm (3σ) |

| Θ: ±1° (3σ) | |

| Chip Size | 1 to 11-mm square *Optional: 15-mm square |

| Lead Frame Size |

|

| Magazine Size |

|

| Wafer Size | Max. 8-inch diameter |

| System Size |

|

| Weight | Approx. 1,600 kg |

Soft Solder Die Bonder (12-Inch)

Die Bonder for Solder Bonding Processes for Power Devices Requiring High Quality Bonding

Features

- Incorporates high performance reduction feeder for solder fusing bonding.

- Incorporates solder spanker (forming) function for high bonding quality.

- Supports large frames up to 100 mm wide.

- Provides flexible support for wafer mapping and traceability.

- Supports wafer sizes up to 12-inch diameter.

Specifications

| Bonding Method | Wire solder feed bonding |

|---|---|

| Bonding Speed UPH | 6,000 (with SOP8 continuous matrix frame and chip size equivalent to 3-mm square) |

| Bonding Accuracy (Using CU Island, Spanker, and Pyramidal Collet) | XY: ±38 µm (3σ) |

| Θ: ±1° (3σ) | |

| Chip Size | 1 to 11-mm square *Optional: 15-mm square |

| Lead Frame Size |

|

| Magazine Size |

|

| Wafer Size | Max. 12-inch diameter |

| System Size |

|

| Weight | Approx. 2,000 kg |

Epoxy Die Bonder

High-Speed, High-Precision Die Bonder Supporting 12-Inch Wafers for IC/Lsi Applications

Features twin dispenser to give high UPH. Uses a unique pick-up system to enable picking up down to a minimum thickness of 15 µm.

Features

- High throughput, small footprint, with quick product switching time, reducing TCO.

- Easily adjustable and includes a reworking function for outstanding ease of operation.

- Minimizes distances between mount positions and preforms, prevents variations over time, and reduces wasteful movements.

- Incorporates newly-developed twin dispensing system to support wide-ranging pastes

- Needle-free pick-up system (optional) enables damage-free pickup

Specifications

| Bonding Method | Epoxy bonding/thermocompression bonding (option) |

|---|---|

| Bonding Speed | 0.18 s/cycle |

| Bonding Accuracy | XY: ±25 µm, 3σ |

| θ: 1°, 3σ (1.0-mm square or over) | |

| θ: 3°, 3σ (under 1.0-mm square) | |

| Chip Size | 0.3 to 8.0-mm square t = 0.075 to 0.5 mm Optional: 0.15 to 2.0-mm square (identification lens change) |

| Lead Frame Size |

|

| Magazine Size |

|

| Wafer Size | Max. 12-inch diameter |

| Utilities |

|

| System Size |

|

| Weight | Approx. 1,600 kg |

| Optional Features |

|

Die Sorter

Only Good Quality Dies Are Picked Up from Diced Wafers, Then Arranged/Stored on a Tray Extensive Proven Support from Mems to IGBT and CMOS Sensors

Features

- High-precision sorting XY: ±38 µm (3σ)

- Supports 6, 8, 12-inch wafers using the change kit

- Supports thin dies using (optional) unique needle-free pickup technology

Specifications

| Wafer Size | 6, 8, 12-inch square |

|---|---|

| Chip Size | 1.5 to 25-mm square |

| Conveyable Tray Size | 2, 3, 4-inch square |

| Layout Accuracy | XY: ±38 µm (3σ) |

| Unit Size |

|

| Weight | Approx. 1,600 kg |

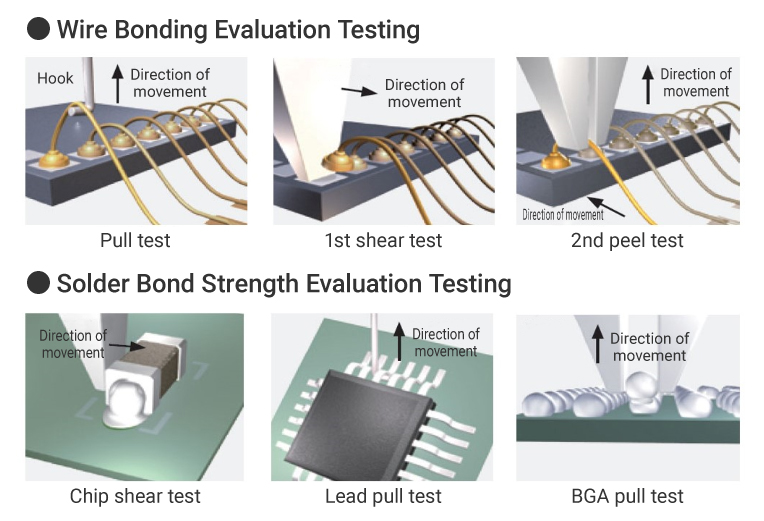

Bonding Tester

From Next Generation Mounting R&D to Quality Control Semiconductor Post-Processing Bond Strength Evaluation Using a Single Unit

Features load detection accuracy and fine adjustment accuracy for measuring gold wire pull (tensile) strength and ball shear strength. Switches sensors to maintain accuracy in low-load regions, even in high-load region measurements, including measurements of die shear strength and solder bond strength.

Features

- Capable of evaluating Au, Al, Cu, and ball, wedge, ribbon, and die bonding.

- The measuring direction and speed is kept constant using three-axis drive control to ensure that consistent results can be obtained by anyone easily.

- Numerical evaluations based on test methods that meet Japanese and international requirements and standards

- ● JIS Z 3198-6/7

- ● MIL-STD-883

- ● JEITA ED 7403/7407

- ● IEC 749

- ● JEITA ED 4703

- ● SEMI G73-0997

Measurement Examples

Specifications

| Measured Load Range | Pull test Push test Peel test |

Max. 20 kg |

|---|---|---|

| Shear test | Max. 100 kg | |

| Measurement Accuracy | ±0.2%FS | |

| Measurement Speed Range | Pull test Push test Peel test |

0.001 to 5 mm/s |

| Shear test | 0.001 to 10 mm/s | |

| Drive Range | X axis | ±50 mm |

| Y axis | ±50 mm | |

| Z axis | Max. 70 mm | |

| Observation Direction | Vertically | 45° |

| Horizontally | ±90° control |

Please inquire for more information on die bonders.

Electronics Equipment Department

Tokyo

81-3-5405-5781

Osaka

81-6-7637-3072