Machinery / Semiconductors and Automation

Materials

Iwatani offers advanced one-stop solutions that encompass all processes encountered in the semiconductor manufacturing sector.

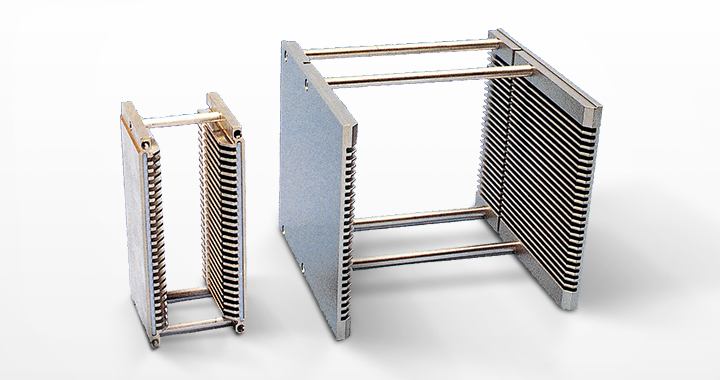

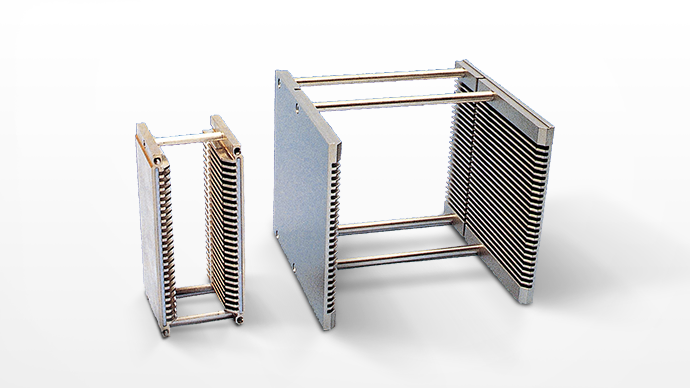

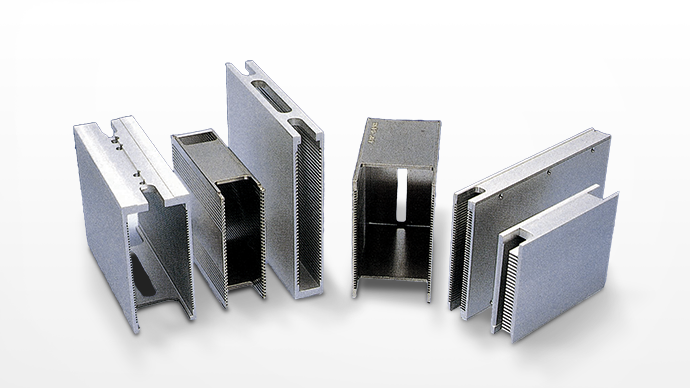

Aluminum Magazine

We Can Offer Extrusion-Integrated Magazines and Assemblies That Can’t Be Produced by Conventional Integrated Molding. Meets Prototyping and Other Small Lot Needs.

- Wafer carrier for semiconductor manufacturing

- Lead frame magazine

- Stick magazine

Features

- Integrated production system from casting, die design and manufacture, extrusion, machining, and surface treatment up to assembly

- Supports surface treatment

Alumite: Standard 6μm, T1-Alumite: Blasting, Kanigen-plating: Standard 7μm, Colored-alumite: Black, red, green, blue, gold - Allows laser engraving of characters and figures.

- Also supports materials cut from the plate.

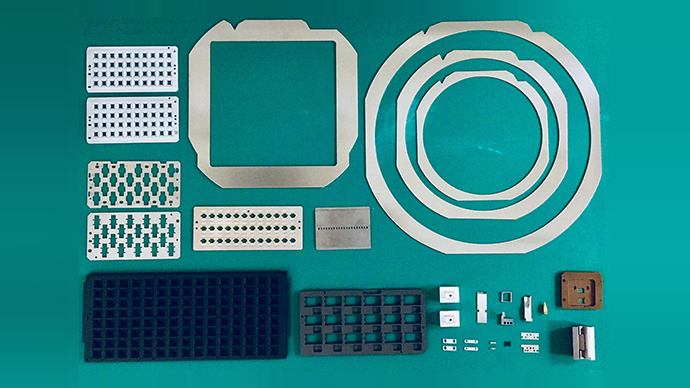

Wafer Rings, Carriers, Trolleys, Jigs

- Design and manufacture of wafer rings, carriers, trolleys, and various jigs based on the specific requirements of each site

- Combined with our systems, enables creation of entire manufacturing site

UV Curable Resin Material and Adhesive for Gaskets

Gasket Formed by the Dispensing Method Without the Requirement for a Mold Meets IPX-7 Requirements While Retaining Flexibility and Toughness

Delivery timeframes and the cost of gasket molds are major challenges in the development of smartphones and smart watches. Our mold-less gasket material features a dispensing UV curable resin. UV curable resin offers high flexibility, overturning the assumption that resins are hard. This allows fine coating and results in waterproof, dustproof, soundproof, and cushioned products characterized by high durability, and also improves production efficiency and cost reduction.

Major Applications and Implementation Examples

- Smartphones, tablets, PCs

- Smart watches

- Digital Cameras

- Loudspeakers

- In-vehicle electronic components (ECU, sensor camera)

Features

- High flexibility: Shore A ≦ 20 or (up to 20 possible)

- High waterproof performance: IPX-7

- Quick curing: UV irradiation can achieve curing within a few seconds

- High shape retention (high thixotropy)

- Fine coating with a width of 0.5 mm also possible

- Surface tack is controlled

Low tack ⇒ Repairability and reworkability

High tack ⇒ Customizable adhesive type

Benefits of Implementation

We can also add various characteristics such as flexibility, toughness, water resistance and durability, along with customization based on customer requirements. The following are some potential benefits of implementation.

- Automation: Solves manual labor costs and labor shortage issues.

- No mold required: Increases degree of design freedom and quality

- Robot dispenser application: Reduces defect rates, eliminates need for special skills and rework

- Online (automatic application and UV curing): Improves productivity.

- Total cost savings

Other

- We invite customers to submit workpieces for us to turn into sample prototypes

- Reduced production time by eliminating the need for molds

- Automates the gasket mounting process

- Unlike molded gaskets, a liquid gasket is applied according to workpiece shape, eliminating the need for a mold.

- Tapes are attached automatically by robot, improving production efficiency and reducing costs.

- Online manufacturing allows instantaneous transfer to the next process.

Specifications

High Durability Type for In-Vehicle Electronic Components

| Major Applications | In-vehicle ECU communication module center | In-vehicle ECU communication modules | |

|---|---|---|---|

| Features | Remarkable hydrolysis resistance Sulfur-free |

High durability High restorability |

|

| Viscosity (MPa・s/25°C) |

0.5 rpm | 400,000 | 836,000 |

| 5.0 rpm | 66,000 | 176,000 | |

| Viscous Index | 0.5 rpm/5 rpm | 6.1 | 4.8 |

| Specific Gravity | 23°C | 1 | 1.2 |

| Fracture Strength (At 23°C) | MPa | 4 | 10 |

| Elongation (23°C) | % | 400 | 800 |

| Hardness | Shore A | 32 | 39 |

| Shore 0 | - | - | |

| Compression Set At 70°C/22 Hours (%) |

25% | 1 | 8 |

| 50% | 3 | 10 | |

| Resistance to Moist Heat at 85°C and 95% Rh | 1,000 h | 1,000 h | |

Specifications

General Purpose Type for Electronic Components

| Major Applications | Smart watch Safety camera |

Smart watch Safety camera |

Tablet Smartphone LCD Screen Digital Camera |

Digital Camera | Lens Robots |

|

|---|---|---|---|---|---|---|

| Features | Wearable proven type Balanced type featuring flexibility and toughness 50% compressible |

Improved-adhesion type; good plastic adhesion | Flexible type | Good metal adhesion | Remarkable hydrolysis resistance Good oil resistance High hardness |

|

| Viscosity (MPa・s/25°C) |

0.5 rpm | 1,400,000 | 720,000 | 870,000 | 740,000 | 800,000 |

| 5.0 rpm | 230,000 | 115,200 | 130,000 | 110,000 | 128,000 | |

| Viscous Index | 0.5 rpm/5 rpm | 6.1 | 6.3 | 6.7 | 6.7 | 6.3 |

| Specific Gravity | 23°C | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| Fracture Strength (At 23°C) | MPa | 4 | 4.2 | 0.9 | 9 | 3.6 |

| Elongation (23°C) | % | 1,800 | 2,460 | 1,300 | 750 | 300 |

| Hardness | Shore A | 17 | 10 | 6 | 36 | 54 |

| Shore 0 | 69 | - | 50 | - | - | |

| Compression Set At 70°C/22 Hours (%) |

25% | 12 | 15 | 32 | 16 | 16 |

| 50% | 12 | 30 | 30 | 16 | - | |

| Resistance to moist heat at 85°C and 95% RH | 200 h | 200 h | 200 h | 200 h | < 1,000 h | |

Exterior Plating Solution

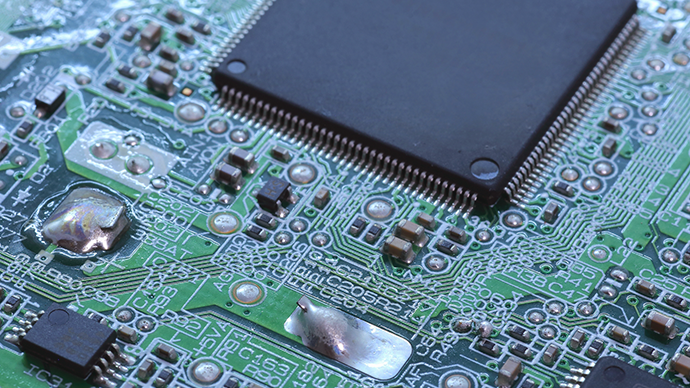

We Offer a Lead-Free SN and SN Alloy Plating Solution Featuring High Corrosion Resistance, Solder Wettability, and Whisker Suppression, Holding the Top Share in Japan’s Market.

The semiconductor components found in personal computers, mobile phones, and AV equipment are plated with Sn and Sn alloys to bond them to printed circuit boards. Our lead-free Sn and Sn alloy plating solution holds Japan’s largest market share.

Types

Sn-Bi plating solution, Sn-Ag plating solution, Sn-Cu plating solution, Sn plating solution

Applications

- Semi-gloss plating process for medium- and high-speed applications

- Wide current density range, supporting barrel and rack plating

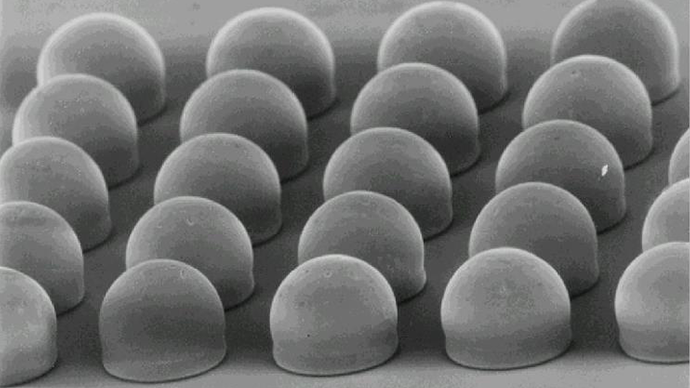

Bump Plating Solution

Wafer Bump Plating Solution: Essential for Advanced Device Production

With device dimensions (primarily smartphones and tablets) continuing to shrink, this product has won high marks as a plating solution for forming wafer bumps, essential to the production of advanced devices.

Types

Sn-Ag plating solution, Sn plating solution

Features

We also offer lead-free bath and high-speed plating products featuring high homogeneity.

Please inquire for more information on materials.

Electronics Equipment

Department

Tokyo

81-3-5405-5781

Osaka

81-6-7637-3072