Materials / Electronic Materials

Subsidiary Materials for Batteries

High Performance Materials to Optimize Manufacturing Processes

In addition to cathode active materials and structural materials, including films and metals for rechargeable batteries, Iwatani handles various subsidiary materials for batteries, including filters, lubricants, and doctor blades. Through offering high performance materials, Iwatani contributes to optimizing customer manufacturing processes.

Products Available

| Product | Units |

|---|---|

| Doctor blades for coatings | Resin, steel, and ceramic doctor blades |

| Cathode and anode filters | Resin filters |

| Pressure roller/drive unit lubricating grease, coil core lubricating spray, dry room (low dew point) environment lubricating grease | Coiling machine lubricating spray, low dew point environment lubricant/grease |

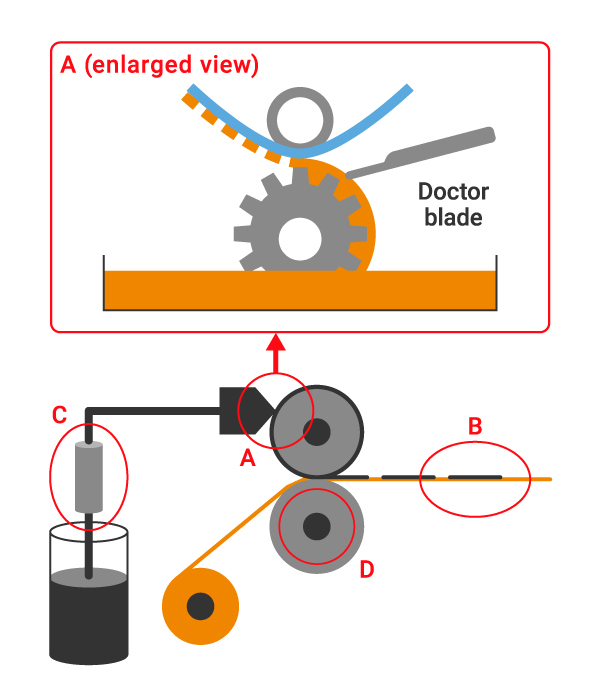

A. Doctor Blades for Coatings

- ・Plastic doctor blades → Reduces costs compared to existing blades

- ・Steel doctor blades are also available.

- ・Used by battery manufacturers

B. PP Single-Sided Tape for Processing Use

- ・Available as a thin film

- ・Products can be customized to customer requirements

- ・Available cut to thin widths

C. Cathode/Anode Filters

- ・Significantly boosts slurry filtering quality → Significantly reduces electrode manufacturing defects

- ・Longer life than existing filters → Lower component replacement costs

- ・Widely used by major battery manufacturers

D. Pressure Roller/Drive Unit Lubricating Grease

- ・Excellent heat (200°C), load, and wear resistance compared to standard mineral grease

-

・Extends lubricating intervals

-

→(1) Lower component replacement costs

- (2) Less frequent maintenance for increased productivity

-

→(1) Lower component replacement costs

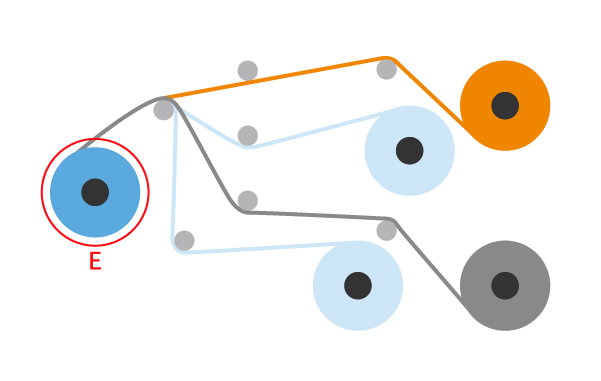

E. Coiling Machine Lubricating Spray

- ・Oil-free, low-friction, normal temperature drying

- ・Reduces winding and drop-out problems to increase productivity → Lower labor costs

- ・Used by major battery manufacturers

Dry Room (Low Dew Point) Environment Lubricating Grease

- ・Consistent lubrication, even over extended service in low dew point and vacuum environments

- ・Chemical resistant (compatible with liquid filling processes)

- ・Safe and nonflammable (ambient temperature range: -20 to 250°C)

-

・Extends lubrication intervals.

-

→(1) Lower component replacement costs

- (2) Less frequent maintenance for increased productivity

-

→(1) Lower component replacement costs

- ・Used by major battery manufacturers

Please inquire for more information.

Electronic Materials Department

Services / Products

Resources & Advanced Materials Top

- Zr (Zirconium) Compounds

- Ti (Titanium) Compounds

- PKS (Palm Kernel Shells)

- Wood Pellet/Torrefied Wood Pellet

- Al (Aluminum) Compounds

- Mg (Magnesium) Compounds

- Phenolic Resins

- Carbon Black

- Fe (Ferrum)

- Rare Earth

- Se/Te (Selenium/Tellurium) Compounds

- Sr (Strontium) Compounds

- Si (Silicon) Compounds

- Ba (Barium) Compounds

- Co (Cobalt) Compounds

- Ta/Nb (Tantalum/Niobium) Compounds

- Ga (Gallium) Compounds

- W (Tungsten) Compounds

- Mo (Molybdenum) Compounds

- Li/Cs/Rb (Lithium/Cesium/Rubidium) Compounds

- Ni (Nickel)

- Epsilon Iron Oxide (Nanoparticles)

- Ceramic Shapes

- Ceramic Honeycomb

- Catalyst Carriers

- Urea

- Stainless Steel

- Aluminum

- Copper/Copper Alloys

- Surface Treated Steel Sheet

- Precision Stainless Steel

- Functional Aluminum Foil

- Hydrogen-Refueling Station Materials

- Clad Metal

- High Alloy Steels/Nickel Alloys

- Magnesium Alloys

- Highly Functional Stainless Steel Foil

- Non-magnetic Stainless Steel

- Beryllium Copper

- Titanium

- Wire Processed Products

- Display Furniture

- Carts

- Heat Treatment Jigs/Cleaning Jigs

- Metal Etching

- FRP (Fiber Reinforced Plastics) Tanks

- Precision/Ultra-Precision Slitting

- Precision Press Processing

- Insert-Molded Articles

- Nursing Care Products

- Secondary Metals

- Eyeglass Parts

- Cast-Iron Pipes

- CFRTP (Carbon Fiber Reinforced Thermoplastics)

- Bonded Dissimilar Materials

- Cu-Fe Alloys

- Medical Titanium Material

- Low-Carbon Aluminum

- Film Slitting Business

- High-Impact Absorbent Acrylic Foam ISR-ACF Series

- Thin Film Heat Dissipating Sheet

- Rework Foam Tape

- Silicone OCA for Foldables

- Silicone OCA for Vehicle Displays

- Optical Urethane Protective Film ISR-TSU Series

- Shock Absorption Sheets ISR-DP Series

- Electric Peeling Tape

- Ultrathin Adhesive Tape

- Low Environmental Impact Protective Film (Recycled Optical PET Protective Film)

- Differential Tape (AB Tape)

- Heavy Water/Deuterium Compounds

- Battery Internal Materials

- Cylindrical Battery Materials

- Square Battery Materials

- Pouch Battery Materials

- Electronic Component Materials

- Semiconductor/HDD Materials (High-Purity Metal, High Functional Packaging Materials)

- Moistureproof Materials/Antifoulants

- Subsidiary Materials for Batteries

- Fuel Cell Related