Materials / Functional Plastics Products

Bio-PET Resins

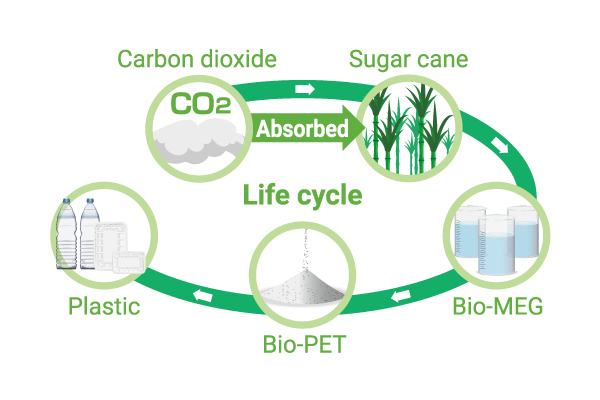

Eco-Friendly Resins of using Bio-Based Raw Materials

Bio-PET resins are manufactured using 30% of bio-based raw materials of monoethylene glycol refined from molasses, a byproduct of sugar cane processing. Iwatani started selling bio-PET resin in 2010 and currently has No. 1 market share in Japan.*

*Based on Iwatani data as of December 2021 (30 thousand tons handled in 2021)

Product Characteristics

1Reducing CO2 emissions by 28%

In order to promote sales of sustainability-conscious raw materials, Iwatani conducts research based on Life Cycle Assessment (LCA), which quantitatively evaluates the impact of raw materials on the ecosystem and the environment from the development stage. In 2011, DNP, Tokyo City University, and Iwatani conducted a joint research and survey on LCA of bio-PET resin. As a result, we found that biomass PET can reduce CO2 emission by 28% (approximately 0.7kg per 1 kg of biomass PET) from the production process to consumption, compared to normal PET.

2Environmentally-friendly resin consisting of 30% bio-based raw material

Biomass PET resin is made from biomass MEG refined from , a byproduct of sugar cane processing. This allows approximately 30% of PET resin to be bio-based.

Major Applications

Bio-PET resin has virtually identical physical properties to petrochemical-based PET resin, making it suitable for a wide range of applications through simple replacement of currently used PET resin.

- Beverage bottles

- Cosmetics containers

- Films

- Sheets, etc.

Please inquire for more information.

Functional Plastics Products Department

Tokyo

81-3-5405-5821

Osaka

81-6-7637-3061

Services / Products

Resources & Advanced Materials Top

- Zr (Zirconium) Compounds

- Ti (Titanium) Compounds

- PKS (Palm Kernel Shells)

- Wood Pellet/Torrefied Wood Pellet

- Al (Aluminum) Compounds

- Mg (Magnesium) Compounds

- Phenolic Resins

- Carbon Black

- Fe (Ferrum)

- Rare Earth

- Se/Te (Selenium/Tellurium) Compounds

- Sr (Strontium) Compounds

- Si (Silicon) Compounds

- Ba (Barium) Compounds

- Co (Cobalt) Compounds

- Ta/Nb (Tantalum/Niobium) Compounds

- Ga (Gallium) Compounds

- W (Tungsten) Compounds

- Mo (Molybdenum) Compounds

- Li/Cs/Rb (Lithium/Cesium/Rubidium) Compounds

- Ni (Nickel)

- Epsilon Iron Oxide (Nanoparticles)

- Ceramic Shapes

- Ceramic Honeycomb

- Catalyst Carriers

- Urea

- Stainless Steel

- Aluminum

- Copper/Copper Alloys

- Surface Treated Steel Sheet

- Precision Stainless Steel

- Functional Aluminum Foil

- Hydrogen-Refueling Station Materials

- Clad Metal

- High Alloy Steels/Nickel Alloys

- Magnesium Alloys

- Highly Functional Stainless Steel Foil

- Non-magnetic Stainless Steel

- Beryllium Copper

- Titanium

- Wire Processed Products

- Display Furniture

- Carts

- Heat Treatment Jigs/Cleaning Jigs

- Metal Etching

- FRP (Fiber Reinforced Plastics) Tanks

- Precision/Ultra-Precision Slitting

- Precision Press Processing

- Insert-Molded Articles

- Nursing Care Products

- Secondary Metals

- Eyeglass Parts

- Cast-Iron Pipes

- CFRTP (Carbon Fiber Reinforced Thermoplastics)

- Bonded Dissimilar Materials

- Cu-Fe Alloys

- Medical Titanium Material

- Low-Carbon Aluminum

- Film Slitting Business

- High-Impact Absorbent Acrylic Foam ISR-ACF Series

- Thin Film Heat Dissipating Sheet

- Rework Foam Tape

- Silicone OCA for Foldables

- Silicone OCA for Vehicle Displays

- Optical Urethane Protective Film ISR-TSU Series

- Shock Absorption Sheets ISR-DP Series

- Electric Peeling Tape

- Ultrathin Adhesive Tape

- Low Environmental Impact Protective Film (Recycled Optical PET Protective Film)

- Differential Tape (AB Tape)

- Heavy Water/Deuterium Compounds

- Battery Internal Materials

- Cylindrical Battery Materials

- Square Battery Materials

- Pouch Battery Materials

- Electronic Component Materials

- Semiconductor/HDD Materials (High-Purity Metal, High Functional Packaging Materials)

- Moistureproof Materials/Antifoulants

- Subsidiary Materials for Batteries

- Fuel Cell Related