Machinery / Semiconductors and Automation

Trim and Forming Systems, Dies

Iwatani offers advanced one-stop solutions that encompass all processes encountered in the semiconductor manufacturing sector.

Trim and Forming Systems (TF Systems)

Lead Processing Systems, With High Shipment Track Record Can Be Combined With Ld/Uld, Printing, and Inspection to Combine Individual Processes, Offering Labor and Manpower Savings.

The design can be customized to allow movement of items between systems. Numerous combined systems have been shipped to date in conjunction with pre- and post-processing systems.

Features

Easy customization allowing flexible configuration, with track record of high shipments in conjunction with pre- and post-processing systems

Main combined systems

- Lead frame loader

- Unloader units, including magazine storage

- Printing units, including laser processing units

- Inspection systems based on image recognition cameras

Customizable design, offering wide-ranging layouts to suit requirements

Main Configurations

- Loader (e.g., stacks, slits, trays, sticks, reels)

- Unloader (e.g., stacks, slits, trays, sticks, reels)

- Laser markings

- Image recognition inspections

- Testing (e.g., OS, characteristics)

Customizable design, offering wide-ranging layouts to suit requirements

Main Specifications

Extensive range available, with processing capacity up to standard 6 t to meet customer requirements

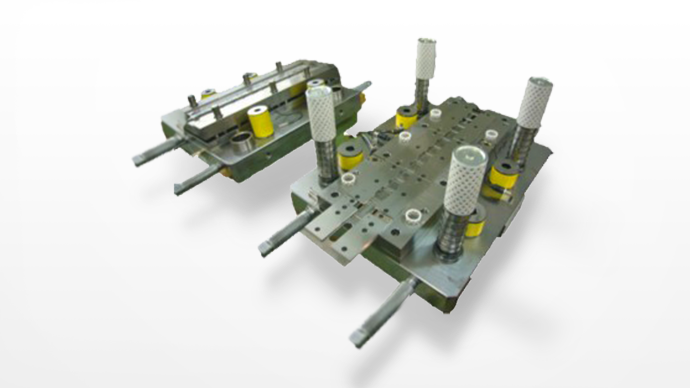

TF Dies

Offering Die Configurations Incorporating Special Cam or Roller Bending to Minimize Package Damage

- Removal technology (minimizing scrap rising and blockage)

Die, punch, and product receptacle profiles are configurable to prevent damage to both products and dies. Iwatani offers optimal profile solutions. - Bending technologies

Traces of contact with the product are minimized to improve product appearance and plating adhesion to die components. Optimal bending solutions, such as cam and roller bending, are offered to suit product profiles. - Die life improvements

Changes to cutting tool materials and special coatings help extend the die life.

Main Applications

Trim and form dies are used at the final stage of semiconductor production to cut out individual packages and form leads.

- Resin cutting

Punching (resin) burrs on parts enclosed by the package exterior, tie bars, or leads - Tie bar cutting

Punching tie bars - Lead cutting

Cutting lead ends and individual packages - Lead forming

Bending lead ends to their final shape

Typical Applications

- SOP products

- DIP products

- SOT products

- SON products

Laser Processing System (Marking, Deburring, Resin Removal)

Lower Semiconductor Defect Rates Achieved Using Laser Irradiation

This system is designed to stamp semiconductor component products. It allows printing on components for each frame, individual components, and two-dimensional code printing. Laser irradiation can also be used to deburr resin components and remove resin. Resin removal is traditionally a process performed using dies. However, in addition to reducing semiconductor defect rates, a laser system helps eliminate die maintenance requirements (for example, replacement work associated with die and punch wear).

Main Applications

Used in processes to stamp product names, manufacturer names, and lot numbers on package surfaces, primarily after cutting out individual packages and forming leads

Typical System Configuration

- Frame supply unit

- Orientation/product confirmation unit (option)

- Laser marking unit

- Visual inspection unit (option)

- Brush unit (option)

- Frame storage unit

Please inquire for more information on trim and forming systems and dies.

Electronic Equipment Department

Tokyo

81-3-5405-5781

Osaka

81-6-7637-3072