Machinery / Semiconductors and Automation

Electronic Circuit Boards

Iwatani offers advanced one-stop solutions that encompass all processes encountered in the semiconductor manufacturing sector.

Electronic Circuit Boards (Printed Circuit Boards)

Compact, Thin, High Heat Dissipation, Heat-Resistant, High Thermal Efficiency, Uv-Resistant Printed Circuit Boards Required for the Development of Next Generation Components

Technologies required for printed circuit boards are becoming steadily more advanced, including increased precision due to reduced component size and high heat dissipation and high heat resistance, due to increasingly diverse usage environments in the development of rigorous next generation electronic components. Iwatani can provide circuit boards with features not available from competitors using its dedicated lines for compact, thin substrates as well as through collaborative materials development with component manufacturers.

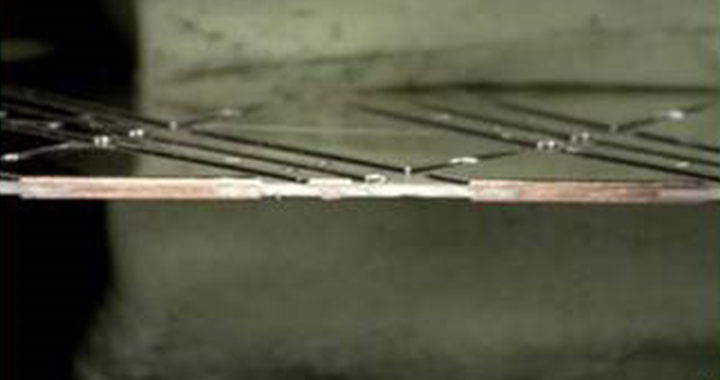

Compact, Thin Substrates

- Manufactured on dedicated lines for compact, thin substrates.

- High-precision patterning using film-less laser direct writing.

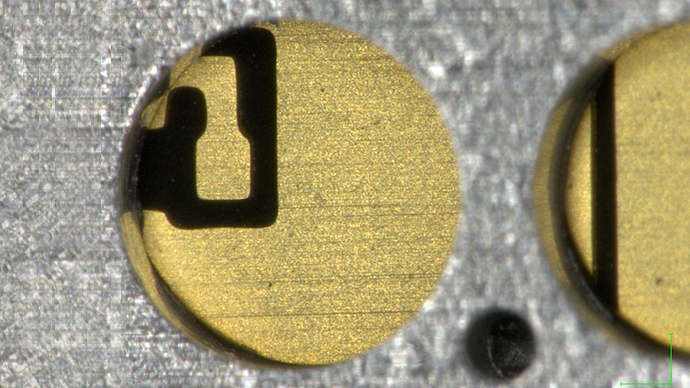

Cavity Substrates

- Configuration with cavity-machined plates attached to printed circuit boards

- Cavity-machined plates can be affixed before or after shipping.

- Control over adhesive seepage

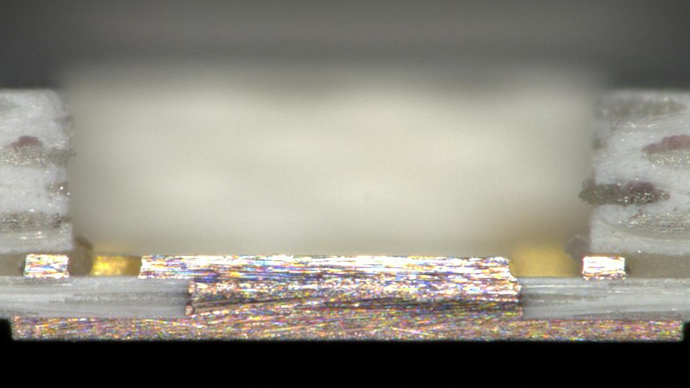

Heat Sink and Bump Substrates

- Copper heat sink formed directly below chips, achieving thermal conductivity comparable to metal circuit boards

- Heat sinks formable using copper plating or etching methods to suit specifications

- High heat dissipation protrusions formed using copper bumps

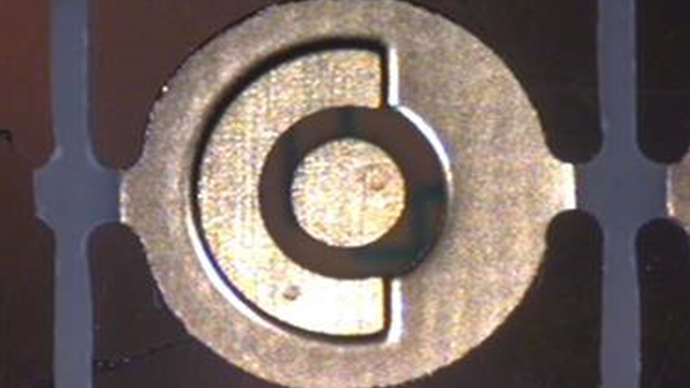

Ceramic Replacement Substrates

- Selectable from substrates with various linear expansion coefficients to suit applications

- Highly heat-resistant materials and UV-resistant ceramic resists

- Combining cavities together with heat sinks, thus replacing ceramic cavity substrates

Please inquire for more information on electronic circuit boards.

Electronic Equipment Department

Tokyo

81-3-5405-5781

Osaka

81-6-7637-3072