Machinery / Semiconductors and Automation

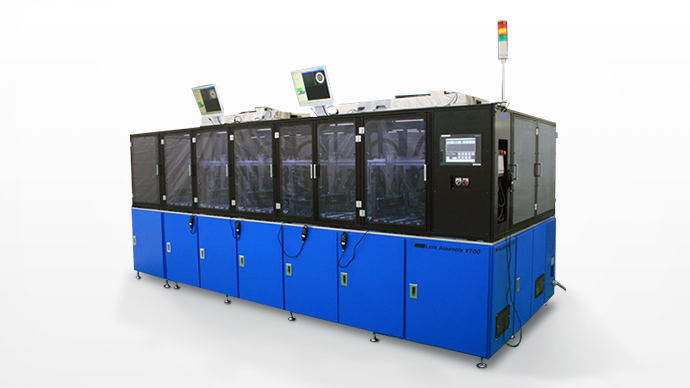

Camera Module Assembly Systems

Iwatani offers advanced one-stop solutions that encompass all processes encountered in the semiconductor manufacturing sector.

Lens Unit Assembly System

High-Speed, High-Precision Assembly of Compact Camera Lens Units

This is a fully-automated assembly system which removes pre-arranged camera lens module components in sequence from a tray and uses image recognition to assemble each component. It supports state-of-the-art high-precision assembly by detecting gate orientation and component positions with high precision.

- Standard support for 13 components and 6 lenses (including barrel).

- Optional support for up to 17 components and 8 lenses (including barrel)

Features

- Capable of high-precision, high quality assembly, supporting state-of-the-art high resolution

- Greatly reduced defect rate, due to pushing (adjusting) operation to support parallel insertion after insertion of each lens

- High-cycle specifications: Minimum machine cycle of 5 s per unit

- Uses imaging system for consistent D cut detection and improved position correction accuracy

- Fully-automated type, requiring simple insertion of workpieces, reducing number of operators required

- Simple product switchover process reduces time taken by 50% compared to previous (for Iwatani products)

- Allows addition of stages to cope with more components

Specifications

| Minimum Teaching Setting Units | 1 µm | |

|---|---|---|

| Operation θ Axis | 0.01° *Minimum settable units |

|

| Axis Accuracy | Main axis | 1 µm |

| YZ axis (part feed assembly axis) | 1 µm *Axis tracking accuracy set in teaching |

|

| Repeatability | Main axis | ±0.001 mm |

| YZ axis | ±0.001 mm *Repeatability for repeated operation with constant range and constant speed |

Gate Cutting System

Full Automation of Gate Cutting After Plastic Lens Molding

Performs high-precision cutting of plastic lenses for use in smartphones and vehicle-mounted devices, and arranges them on dedicated trays by cavity. Uses a heated cutter with an original servo drive to not only ensure a highly-accurate cut face, but also minimize any distortion due to cutting. Production history (traceability) is also available as an option.

Main Applications

- Plastic lenses (for smartphones, vehicle-mounted devices, SLR cameras, digital cameras, projectors, etc.)

- SLR camera viewfinders, etc.

Please inquire for more information on camera module assembly systems.

Electronic Equipment Department

Tokyo

81-3-5405-5781

Osaka

81-6-7637-3072