Machinery / Semiconductors and Automation

Visual Inspection Systems

Iwatani offers advanced one-stop solutions that encompass all processes encountered in the semiconductor manufacturing sector.

Chip Component Visual Inspection Systems

Uses Image Processing With Proprietary Software to Determine Chip Component Surfaces (4/6 Faces) System Design Ensures Consistent Inspection Accuracy and Avoids Damaging Workpieces

Features

- Image processing details: Scratches, chipping, dirt, contamination, dimensional detection, etc.

- Image processing speed: Varies depending on workpiece and image processing details

- System processing speed: Max. 5,000 units/minute

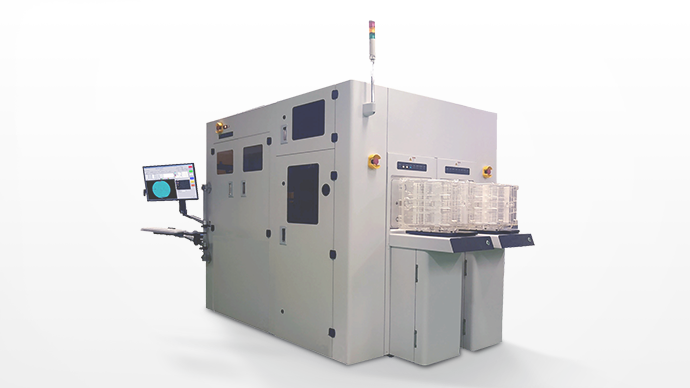

Wafer Visual Inspection Systems

Visual Inspection System Using Proprietary “Adaptive Learning” Inspection Function

Features

- Inspection items: Dirt, discoloration, contamination, cracking, chipping, scratches

- Adaptive learning software: Eliminates erroneous interpretations due to product variations.

Please inquire for more information on visual inspection systems.

Electronics Equipment Department

Tokyo

81-3-5405-5781

Osaka

81-6-7637-3072