Machinery / Semiconductors and Automation

Cleaning Systems

Iwatani offers advanced one-stop solutions that encompass all processes encountered in the semiconductor manufacturing sector.

Ultrasonic Cleaner

Easy to Clean Parts Integrated Device with Washer and Distiller

Compatible Cleaning Solutions

Alcohol, Class I petroleums such as toluene, MEK, thinner, etc.

Washing Tank Size

- Width

- 500 mm

- Depth

- 250 mm

- Height

- 300 mm

Applications

Cleaning and drying precision parts, ferrule pipes, electronic parts, optical glass parts, and automobile parts, coating of semiconductor parts, extraction of filled solution from within parts, etc.

Organic Solvent Cleaner (Organic Solvent Recovery System)

Recycles Waste Solvents Discharged from Various Manufacturing Plants

The cleaning solutions (waste solvents) discharged from production processes of various manufacturing plants contain various substances. For this reason, such solutions are disposed of as waste. This product makes it possible to extract recyclable solvent components from these solutions.

Recoverable Solvents

Waste thinner, toluene, ethyl acetate, isopropyl alcohol, ethanol, methanol, xylene, butyl acetate, chlorine-based, chlorofluorocarbon-based, acetone, MEK, MIBK, kerosene, ethylene glycol-based, hydrocarbon-based cleaning agents, and Class 2 and 3 petroleum (certain water-based solvents also recoverable)

*Strong acids, strong bases, water, etc. unrecoverable

Spray-Shower Cleaning Machine

Enables Cleaning of Equipment and Printing Parts/Components Adhered with Ink, Paint, Pigments

The ability to wash parts previously washed by hand reduces cleaning times and human burdens. The attached vacuum distillation continuous recovery device allows reuse of cleaning solutions.

Compatible Cleaning Solution

Alcohol, Class I petroleums such as toluene, MEK, thinner, etc.

Applications

- Inks, paints, pigments adhering to equipment parts (equipment, ink pans, toning containers, etc.)

- Printing parts at a gravure printing company

- Tanks for paint toning

- Automotive parts

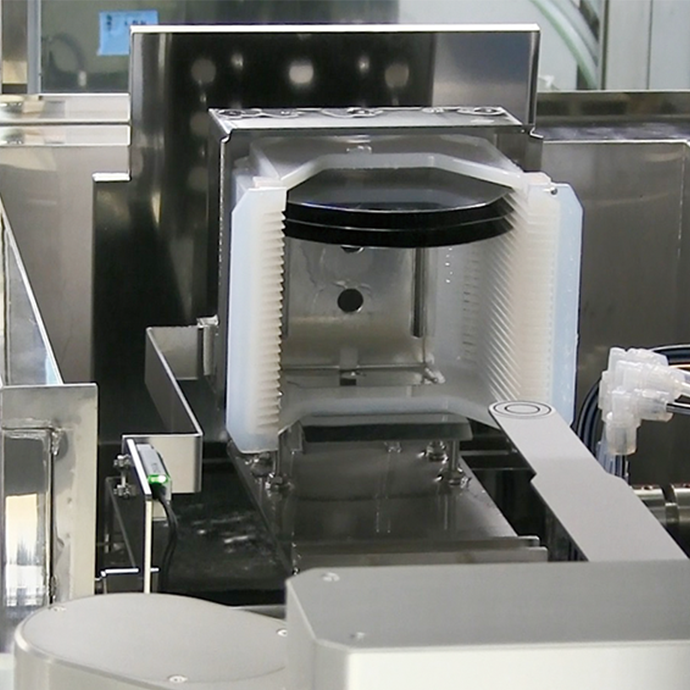

Lift-off System

Removes Organic Matter and Metals on Resists

This facility is primarily used for the lift-off process that removes organic matter and metals from resists (single-wafer processing for mass production). This product makes it possible to set the specifications for each process and to customize the equipment based on wafer conditions (difficulty of peel-off, ease of damage, ease of breakage).

Customization Examples

- Loader

- Tanks for peeling

- Rinse tank

- Spin chamber

- Unloader, etc.

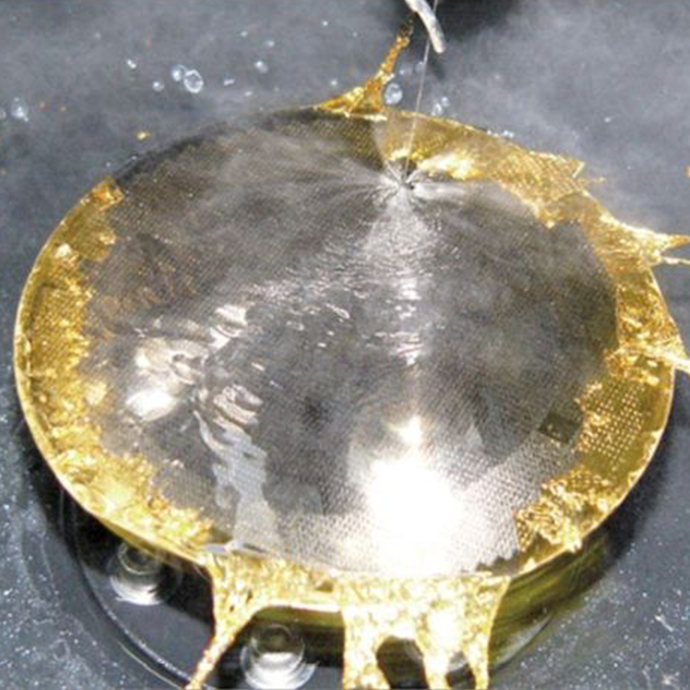

State of metal film peeling

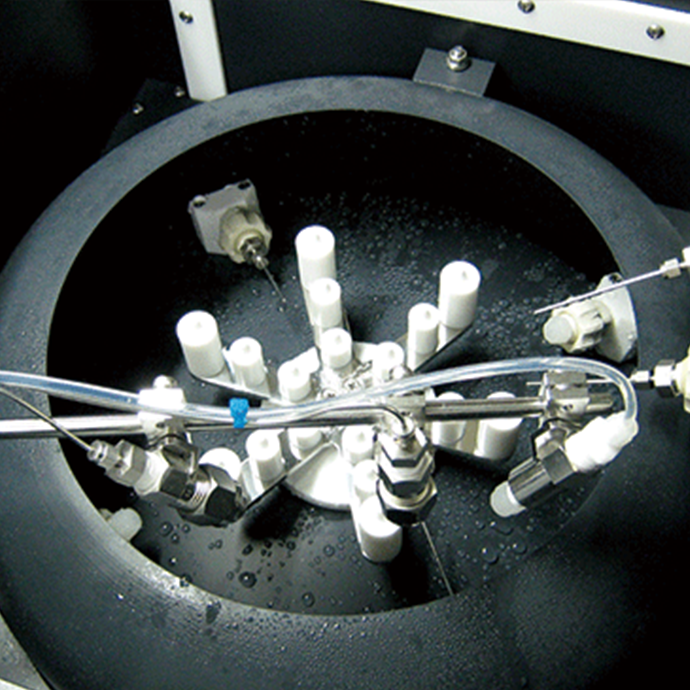

Jet chamber

Inversion tank

Please inquire for more information on cleaning systems.

Electronics Equipment Department

Tokyo

81-3-5405-5781

Osaka

81-6-7637-3072