Conservation of Resources

Our Policy

Resource conservation is vital to realizing a sustainable society. Our Environmental Policy includes the following provisions: “1. We will work to establish a . . . recycling-oriented society through research and development of technologies that utilize resources effectively . . .,” and “2. We will endeavor to conserve resources . . . through our business activities.” Accordingly, we regard resource conservation as a key issue to be considered in business activities. The Iwatani Group strives to conserve resources in various ways, including making more effective use of water resources and used plastics recycling.

Environmental Initiatives Through Business Activities

Putting Water Resources to Effective Use

Iwatani Australia Pty Ltd., a group member company, mines titanium ore, a raw material in titanium dioxide and mineral sands such as the zircon sand used in semiconductors and electronic materials in Western Australia. In the dressing stage after mining, Iwatani Australia relies on water to separate mineral sands from other sand and dirt through gravity separation. To minimize water consumption, rather than releasing this water as is after use, it stores the water in a large reservoir, then reuses the water from the higher levels of the reservoir after sand, earth, and other impurities have settled out.

Recycling Used Plastics

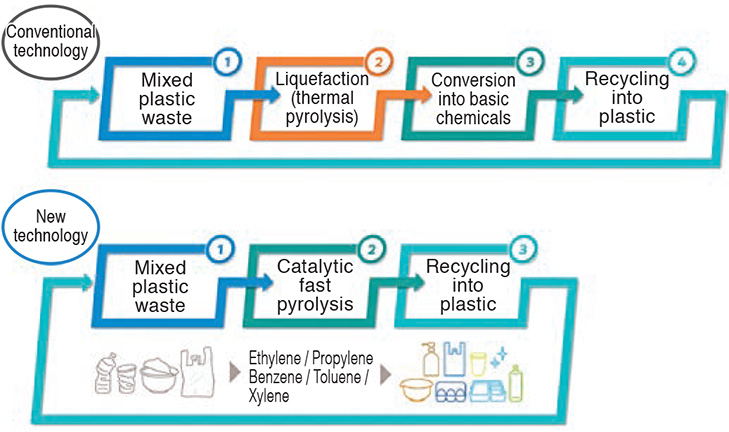

In June 2020, R Plus Japan, Ltd., a company established by Iwatani in partnership with 12 other companies, began activities related to used plastics recycling. Harnessing recycling technologies utilizing solutions developed by US biochemical startup Anellotech Inc., the company applies chemical methods to recycle plastics including PET bottles directly into raw materials. Since this method requires fewer steps than conventional methods, it helps minimize CO2 emissions and energy use. This new company is striving to commercialize its recycling technologies by 2027.

Eco-friendly PET Resins

Iwatani is actively developing and deploying PET resins that have low environmental impact. We have developed and brought to market biomass resin, a plastic made by replacing monoethylene glycol, which accounts for 30% of all raw materials in conventional resins, with plant sourced materials. We have also developed a highly recyclable aluminum catalyst resin that has been adopted as a new resin to promote PET recycling. We are also planning to introduce aluminum catalyst biomass resins that take advantage of the features of both biomass resin and aluminum catalyst resin to realize both reduced CO2 emissions and high recycling rates.

Ensuring the Stable Supply of Helium

Essential in state-of-the-art technologies and healthcare, helium is a rare natural resource produced in a handful of countries. Iwatani seeks to ensure a dependable supply of helium by procuring it from two countries, Qatar and the United States, from whom we have secured direct importing rights. Our organization includes two of Japan’s largest helium centers: the Tokyo Helium Center (in Inashikigun, Ibaraki Prefecture) and Osaka Helium Center (the city of Osaka), further stabilizing supply capabilities. Each uses high-efficiency helium recovery equipment to cut losses during filling processes to oneeighth previous levels and to make the most effective use of this rare resource. In addition, the Tokyo Helium Center uses equipment that allows production of ultra-high purity (99.99999%) helium gas with a purity of the industry’s highest standards. Iwatani plans to introduce this dependable supply of helium to meet growing demand not just in Japan, but in other markets, including China, Southeast Asia, and United States.