Machinery / Joining and Cutting Technologies

Welding and Joining Technologies

As a supplier of industrial gases, We have perfected various joining technologies centered on arc welding. We offer a wide range of high-quality joining solutions, including arc welding, resistance welding, plasma welding, laser welding, and brazing.

Arc Welding

Shield Gas

Iwatani manufactures and offers a broad range of shield gases for welding to meet all welding requirements, including carbon dioxide, argon, helium, hydrogen, and mixed gases. We support the improvement of welding quality and stable supply with our know-how and abundant lineup as a gas manufacturer.

Cylinder Gas

Iwatani delivers compressed gas in the form of cylinders, filled in its own manufacturing plant, and achieves a stable supply through its nationwide supply network. We meet all welding requirements by offering the diverse range of Shield Master Series® premix gases, which are manufactured by mixing multiple gases, as well as single gases such as carbon dioxide and argon.

Features

Welding methods matched with base metals improve welding quality in all industries, achieving both high efficiency and cost reductions. We also design tailored mixing ratios and on-site mixing to meet customer challenges.

Specifications

For Mild Steel/Low Alloy (MAG)

| Product name | Composition | Target material | Features | Applications |

|---|---|---|---|---|

| Acomgas | Ar+CO2 | Mild steel | Low spatter, arc stability, MAG gas with high versatility | Steel frames, bridges, shipbuilding, etc. |

| Acom Eco | Ar+CO2 | Mild steel medium plate thickness | Low spatter, low fume, economical MAG gas, improved working environment with CO2 welding | Steel frames, bridges, shipbuilding, etc. |

| Acom HT | Ar+CO2 | Thin plate high-tensile steel | Low spatter, high speed, improved bead appearance, improved weld metal properties | Vehicles, transport equipment, office equipment, etc. |

| AcomZⅡ | Ar+CO2 | Zinc-plated steel sheets | Low spatter, high speed, improved pit resistance, usable for general mild steel | Housing equipment, vehicles, etc. |

| Hi-acom | Ar+CO2+He | Mild steel medium-thick plate | High spatter reduction, high speed, improved bead appearance, excellent arc stability over medium to high currents | Steel frames, bridges, shipbuilding, etc. |

| Acom FF | Ar+CO2+O2 | Mild steel thin sheets, zinc plating | The formation of wide beads suppresses undercuts and enables high speed | Vehicles, transport equipment, etc. |

For Al/Al Alloy (MIG/TIG)

| Product name | Composition | Target material | Features | Applications |

|---|---|---|---|---|

| Hi-almate A | Ar+He | Thin Al alloy/Cu alloy, pulse MIG/TIG laser Pulse MIG/TIG laser |

Improved weld penetration, high-speed, improved blow hole resistance, improved bead appearance | Railroad vehicles, LNG tanks, aluminum vessels, EV/FCV, etc. |

| Hi-almate S | He+Ar | Thick plate Al alloy/Cu alloy Pulse MIG/TIG laser |

Improved weld penetration, high speed, improved resistance to blow holes, improved bead appearance | Railroad vehicles, LNG tanks, aluminum ships, EV/FCV, etc. |

For Stainless Steel (MIG/TIG)

| Product name | Composition | Target material | Features | Applications |

|---|---|---|---|---|

| Tigmate | Ar+H2 | Stainless steel/plasma welding | Improved weld penetration, high speed, adjustable mixing ratio using TIG plate thickness | Kitchen equipment, piping, etc. |

| Hi-migmate | Ar+He+CO2 | Stainless steel/pulse MIG | High deposition rate, high speed, improved bead appearance, high spatter reduction, high welding quality | Vehicles, railroad vehicles, chemical plants, etc. |

| Migmate | Ar+O2 | Stainless steel/pulse MIG | Arc stability, low spatter deposition, improved welding efficiency | Vehicles, piping, etc. |

For Ultrathin Plate Brazing (MIG)

| Product name | Composition | Target material | Features | Applications |

|---|---|---|---|---|

| Blazemate | Ar+He+H2 | Ultrathin plate mild steel/stainless steel/MIG | Good bead appearance and reduced spatter compared to Ar brazing | Vehicles, sheet metal, ducts, etc. |

Practical Examples (by Material)

- Mild steel: Acom

- Thin sheets (high-tensile steel sheets): Acom HT

- Mild steel thick plate: Hi-acom

- Zinc plating: Acom ZⅡ

- Stainless: Tigmate (TIG welding)

- Aluminum: Hi-almate (TIG/MIG welding)

*We have a large number of shield gases in addition to the mixed gases listed above. Please inquire for more information.

Liquid Gas

Shield gas for welding with liquid gas for large storage capacity

If the amount used is larger than the compressed gas supplied with the high-pressure cylinder, we propose the supply of liquid gas. Depending on the amount used, offer supply in portable low-temperature liquid gas containers (LGCs) or tank trailer supply in stationary cold evaporators (CEs).

Liquid gas container (LGC)

Cold evaporator (CE)

Gas Supply System

In addition to proposing optimal gas supply methods, we also have a diverse lineup of gas equipment and gas applications that make effective use of the characteristics of industrial gas.

Liquid gas vaporizer assembly unit

Gas mixing device (Chiyoda Seiki Co., Ltd.)

Gas mixing device (Yutaka Engineering Corporation)

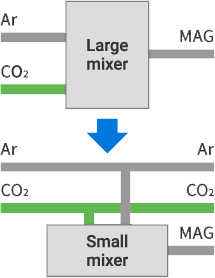

With the diversification of steel types and products, it is required to select a shield gas suitable for each type of welding. By using a small mixer with the “double piping” technique as opposed to the conventional method of producing a mixed gas by passing argon and carbon dioxide through a large mixer, it can be used not only as a mixed gas but also as argon and carbon dioxide, widening the range of welding.

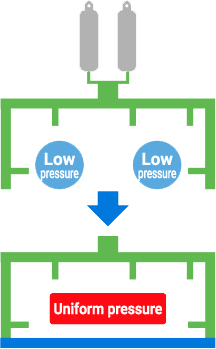

A stable supply of shield gas contributes significantly to welding quality. Loop piping is essential to the stable supply of shield gas. Even in places where pressure drops due to pipe pressure losses are significant and flow rates are unstable, using loop piping increases pipe cross-sections, reducing pipe pressure drops. In addition, the pressure inside the loop can be made highly uniform.

High-Shield Hose

High Quality Gas Hose Ideal for Supplying Welding Gas

In MIG and TIG welding, hose shield performance to supply the high-purity shield gas is important. High-Shield Hose features a four-layer structure with high gas barrier properties that suppress permeation of the atmosphere from the exterior. Compared to other materials, the permeability coefficient in comparing the permeability of water and oxygen is negligible, showing outstanding barrier properties. Especially in aluminum welding, it suppresses blow hole generation due to moisture.

Welding Material

Iwatani proposes a broad range of welding materials, including mild steel, stainless steel, and aluminum sourced from Japan and overseas. We can offer wide-ranging proposals as we handle special joining materials, including for brazing.

Welding materials (Kobe Steel, Ltd.)

Welding materials (Daido Steel Co., Ltd.)

[Manufacturers Represented]

- Kobe Steel, Ltd.

- Daido Steel Co., Ltd.

- Nippon Steel Welding & Engineering Co., Ltd.

- Sumitomo Electric Industries, Ltd.

- Nippon Welding Rod Co., Ltd.

- Hyundai Welding Japan Co., Ltd.

- Kuang Tai Metal Japan Co., Ltd.

- ESAB SeAH Corp.

- ESAB

- MENAM STAINLESS WIRE PCL.

- Venus Wire Industries PVT. Ltd., etc.

Welding Equipment

We provide various products of major arc welding manufacturers in Japan and overseas. In addition to offering welding robots and welding machines made overseas, we provide design support for welding jigs and welding systems.

Welding machines (Daihen Corporation)

Arc welding robot (Daihen Corporation)

Arc welding robot (Yaskawa Electric Corporation)

[Manufacturers Represented]

- Daihen Corporation

- Yaskawa Electric Corporation

- Kobe Steel, Ltd.

- Fronius Japan K.K., etc.

Lubricant

Unparalleled sustainability due to ultra-high lubricity additives

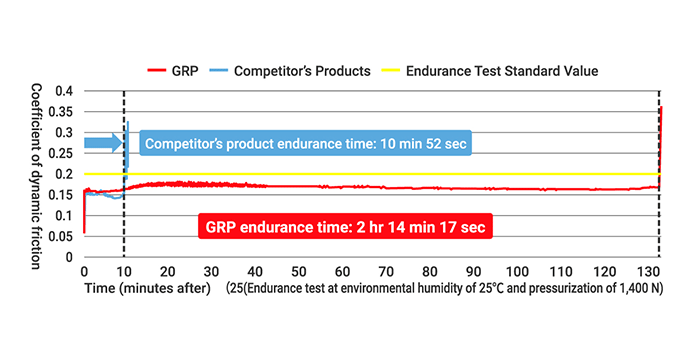

GRP oil spray (300 ml) (GRP Co., Ltd.)

Comparison of endurance time between GRP’s oil spray and competitor’s product (GRP Co., Ltd.)

GRP Oil Spray/Grease Spray

By applying GRP’s oil spray/grease spray, the contained additives react with the metal sliding area to form a strong fixing film (eutectic film). Such a film has the technical conditions required for lubricating oil, and the metal sliding area coated on the eutectic film maintains its lubricating performance even after the oil has dried.

Other Products Available

We offer a wide range of products that are indispensable for welding processes, including pre-welding and post-welding processes.

Non Spatter adhesion inhibitor series (Ishihara Chemical Co., Ltd.)

- Spatter adhesion inhibitor (Ishihara Chemical Co., Ltd.)

- Cutting, polishing whetstone, equipment (Nippon Resibon Corporation, Ichiguchi Corporation)

- Oil adsorbent (Kakui Co., Ltd.)

- Tungsten electrode rod

- Gas cutting machine

- Dust protective mask

- Protective equipment for welding

- Dust collector, fume collector, general ventilation system, etc.

Resistance Welding

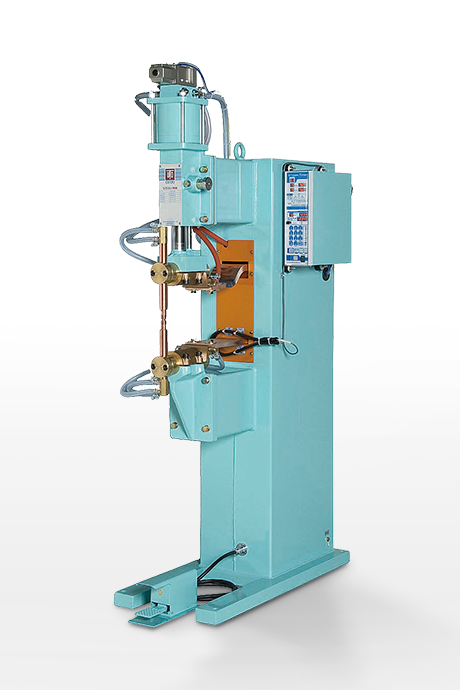

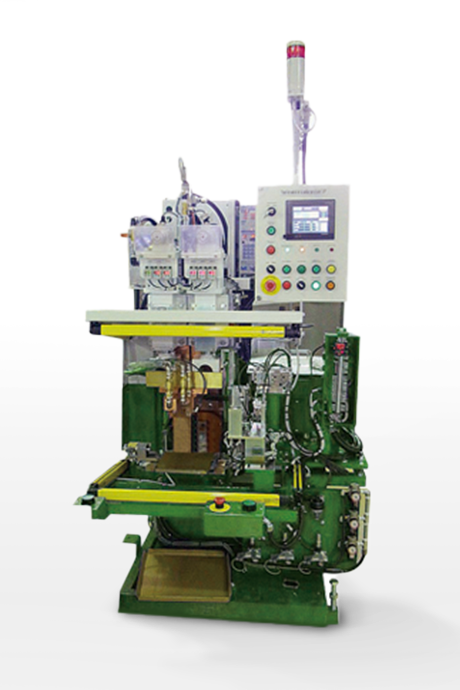

We also support various stationary spot-welding machines as well as customized machines suited to special applications and/or customer requirements.

General purpose stationary spot-welding machine (Chuo Seisakusyo, Ltd.)

Stationary spot-welding machine (Dengensha Toa Co., Ltd.)

Automatic resistance welding machine (Chuo Seisakusyo, Ltd.)

Inverter Type Capacitor Welder Linear Wave Series (Dengensha Toa Co., Ltd.)

Laser Welding

Fiber laser (IPG Photonics Corporation)

Needs for welding with high-speed and high-precision and joining of dissimilar materials are increasing, and we provide total support from test welding to introduction of fiber lasers, hybrid lasers, and remote lasers.

Other Welding Machines

Our range includes plasma welding, hand-held laser welding, brazing, high frequency brazing, and longitudinal joint welding.

Plasma welding machine (Daihen Corporation)

Plasma welding machine (Nippon Steel Welding & Engineering Co., Ltd.)

Welding Materials Center

Ordering operations are carried out at the East and West Welding Materials Centers, involving vast inventory warehouses, including of overseas products, for fast and secure delivery of products nationwide.

East Japan Welding Products Center

2-1, Ryutsu-danchi 2-chome, Koshigaya-shi, Saitama 343-0824, Japan

TEL : 81-48-985-1811

FAX : 81-48-985-1815

West Japan Welding Products Center

51-2, Shibo-cho 1-chome, Takatsuki-shi, Osaka 569-0823, Japan

TEL : 81-72-677-9263

FAX : 81-72-677-9267

Joining and Cutting Technologies Product List