Machinery / Joining and Cutting Technologies

Shield Master®

Shield Master series, the No.1 mixed welding gas brand, was developed to meet the requirements of various applications and base materials. With a wide lineup, we have improved welding quality and reduced costs by improving efficiency. We also design tailored mixing ratios and on-site mixing to meet customer challenges.

Acom

Iwatani’s Mixed Gas for Welding is the Basis of the Shield Master Series

Highly Versatile MAG Gas, Applied for Various Types of Welding

Major Applications

Vehicles, transport equipment, construction machinery, etc.

Features

- Reduces generation of spatter

- Arc stability

- Improved welding speed

- Improved bead appearance

- High quality welding with low slag and low spatter

Specifications

| Product Name | Composition | Target Material | Applications |

|---|---|---|---|

| Acomgas | Ar+CO2 | Mild steel | Steel frames, bridges, shipbuilding, etc. |

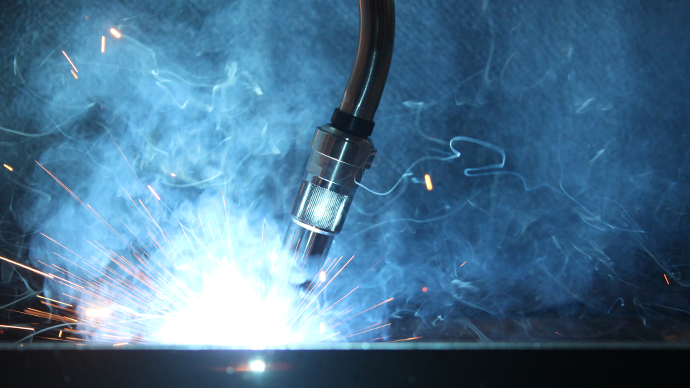

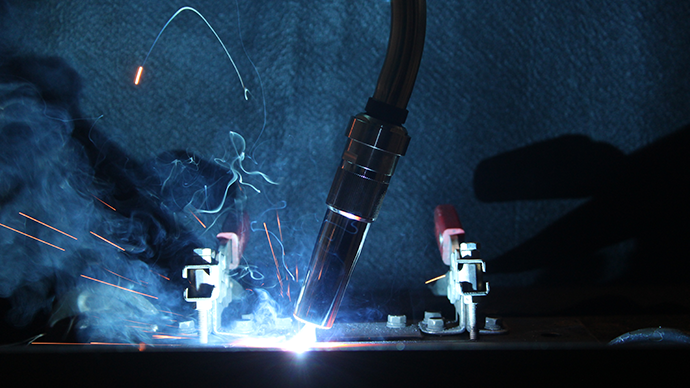

Welding with carbon dioxide

Welding using Acomgas

Acom HT

Achieves High Quality Welding of Thin Sheets/High-Tensile Steel Sheets

Major Applications

Vehicles, transport equipment, office equipment, etc.

Features

- Reduces spatter generation

- Reduces slag adhesion

- Suppression of melt-off by improving high-speed weldability

- Improved bead appearance

- Optimal for high efficiency of thin plate welding

Specifications

| Product Name | Composition | Target Material | Applications |

|---|---|---|---|

| Acom HT | Ar+CO2 | Mild steel medium-thick plate | Vehicles, transport equipment, office equipment, etc. |

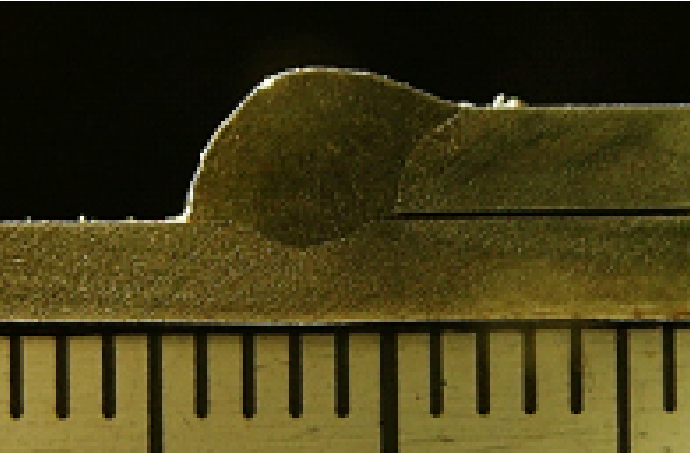

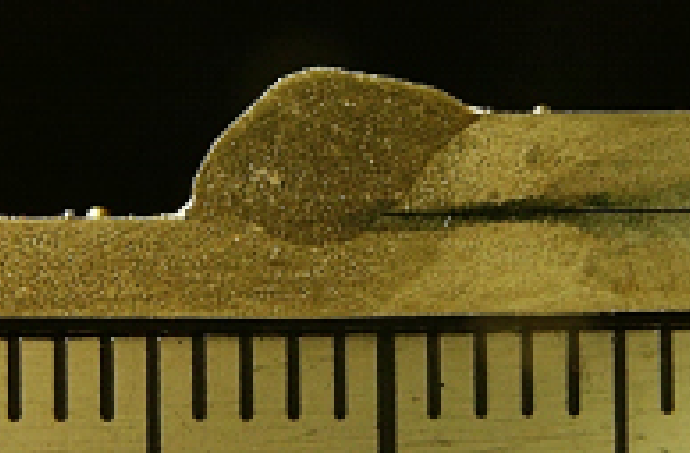

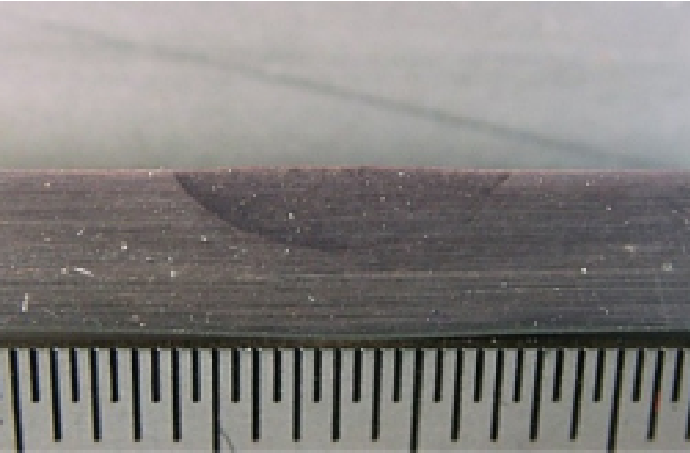

| Applied Gas | Bead Cross-sectional Shape | Lateral Welding bead Appearance |

|---|---|---|

| Acom HT |  |

|

| Ar+20%CO2 |  |

|

*Comparison of penetration and bead appearance between Acom HT and normal MAG welding

(Welding conditions: 170 A, 18 V, wire φ1.0, plate thickness t2.3)

Acom ZⅡ

Fastest in the Industry

Solves Zinc-Plated Steel Sheet Welding Issues with High Quality Welding

Major Applications

Housing equipment, vehicles, etc.

Features

- Reduces spatter generation

- Reduction in pits and blow holes

- Arc stability in the low current range

- Blow hole prevention and low spatter

Specifications

| Product Name | Composition | Target Material | Applications |

|---|---|---|---|

| Acom ZⅡ | Ar+CO2 | Zinc-plated steel sheets | Housing equipment, vehicles, etc. |

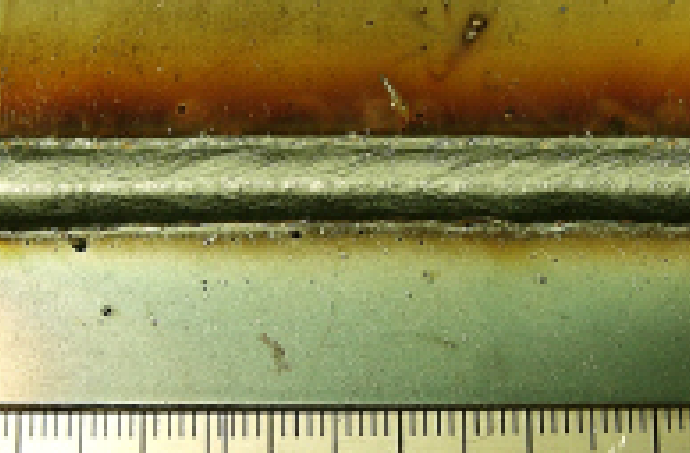

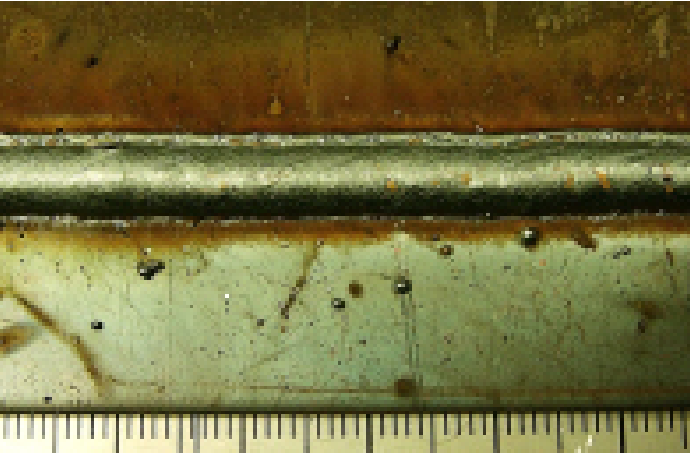

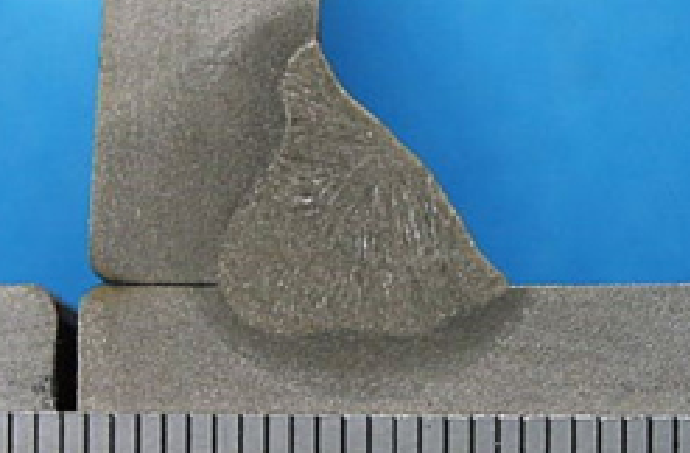

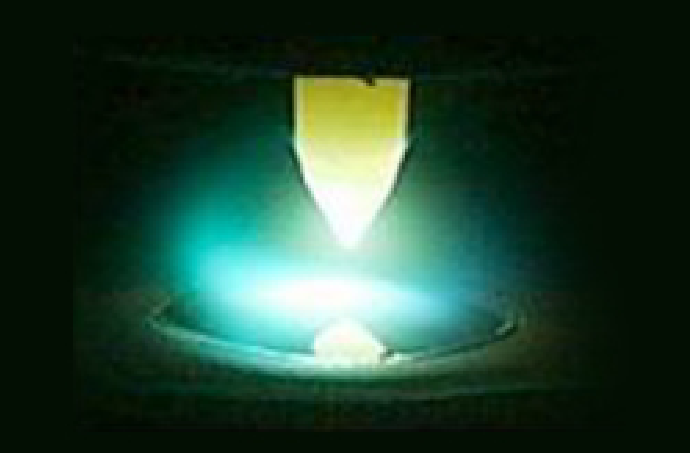

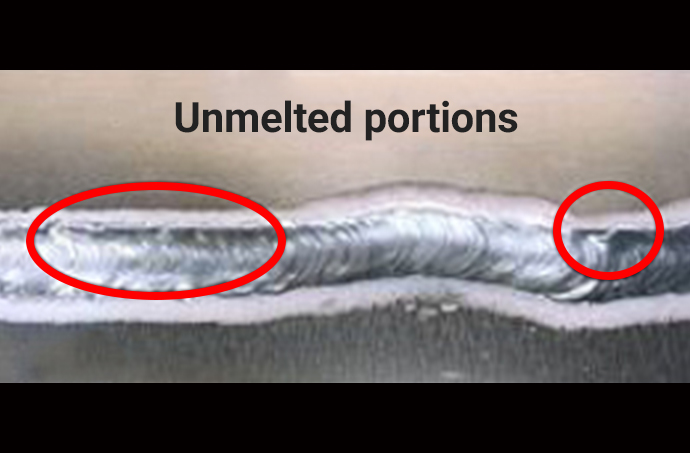

| Acom ZⅡ | CO2 |

|---|---|

|

|

Electrodeposited steel sheets: t1.5, Welding current: 130 A, Fillet welding

Hi-Acom

Achieves Deep Weld Penetration and High-Speed Welding

Shield Gas that Achieves Drastic Reduction in Spatter with Outstanding Arc Stability

Major Applications

Steel frames, bridges, shipbuilding, etc.

Features

- Drastic reduction in deposited spatter

- Speed-up

- Improved bead appearance

- Outstanding arc stability in the medium- to high-current range

- Improved weld penetration

Specifications

| Product Name | Composition | Target Material | Applications |

|---|---|---|---|

| Hi-Acom | Ar+CO2+He | Mild steel medium-thick plate | Steel frames, bridges, shipbuilding, etc. |

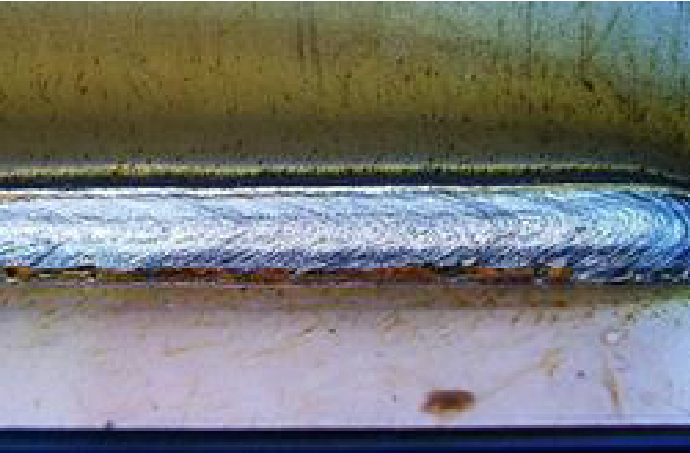

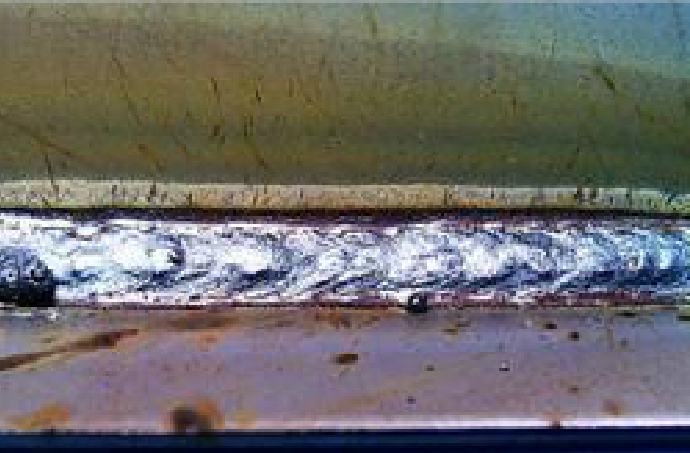

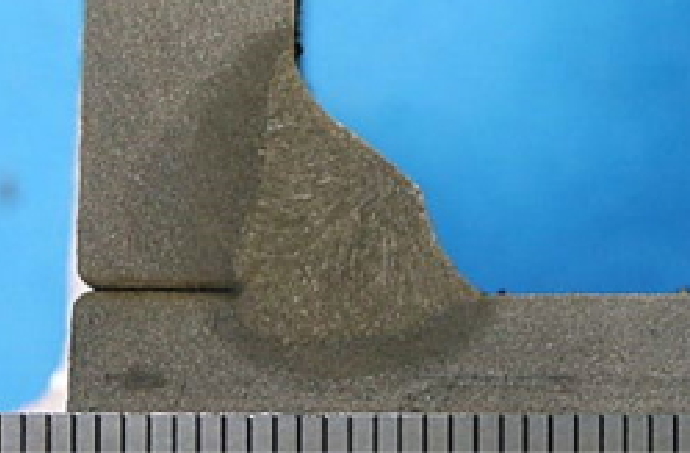

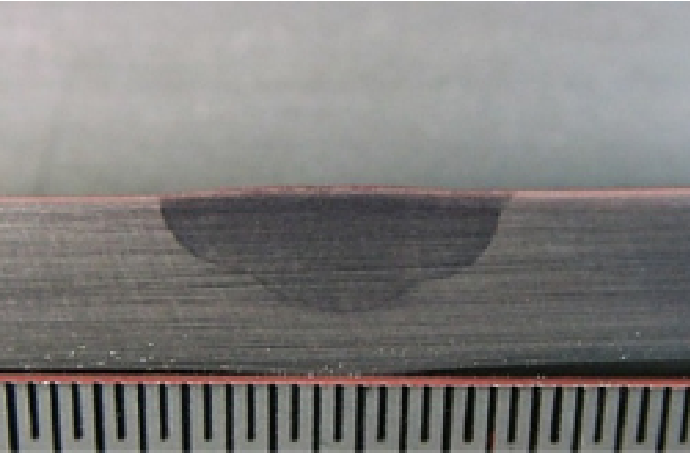

| Hi-Acom | Ar/CO2=80:20 |

|---|---|

|

|

Conditions Current: 250 A, Voltage: 29 V

Comparison of Weld Penetration

| Hi-Acom | Ar/CO2=80:20 |

|---|---|

|

|

Tigmate

Achieves Increased Speed of Stainless Steel Welding

Shield Gas for TIG Welding to Prevent Thermal Distortion

Major Applications

Kitchen equipment, piping, etc.

Features

- Deep and wide weld penetration

- Speed-up

- Mixing ratio can be adjusted according to plate thickness

- Higher efficiency of TIG welding and improved welding speed

Specifications

| Product Name | Composition | Target Material | Applications |

|---|---|---|---|

| Tigmate | Ar+H2 | Stainless steel, plasma welding | Kitchen equipment, piping, etc. |

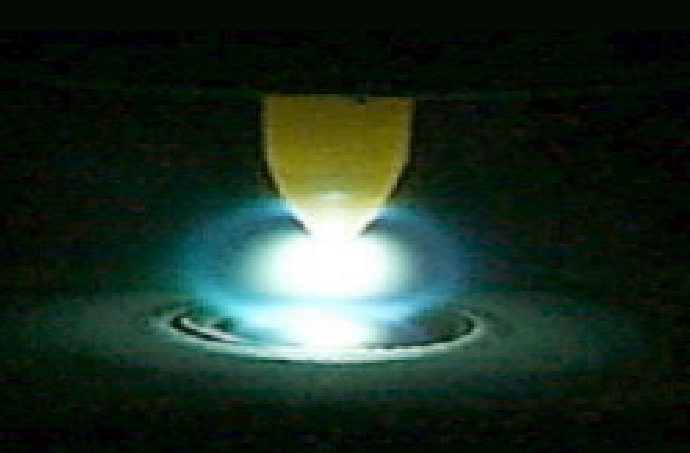

| Tigmate | Argon |

|---|---|

|

|

| Argon | Adding 3% Hydrogen |

|---|---|

|

|

| Adding 5% Hydrogen | Adding 7% Hydrogen |

|---|---|

|

|

Hi-Almate

Improved Penetration Performance Due to Mixture of Helium and Argon

Shield Gas for Welding Aluminum and Copper Alloys

Major Applications

Aircraft, railroad vehicles, LNG tanks, FCV/EV-related parts, etc.

Features

- Deep and wide weld penetration

- Speed-up

- Improved blow hole resistance

- Improved bead appearance

Specifications

| Product Name | Composition | Target Material | Applications |

|---|---|---|---|

| Hi-Almate A | Ar+He | Al alloy, Cu alloy, pulse MIG/TIG | Aircraft, railroad vehicles, LNG tanks, FCV/EV-related parts, etc. |

| Hi-Almate S | He+Ar | Al alloy, Cu alloy, pulse MIG/TIG | Aircraft, railroad vehicles, LNG tanks, FCV/EV-related parts, equipment for thick plate welding, etc. |

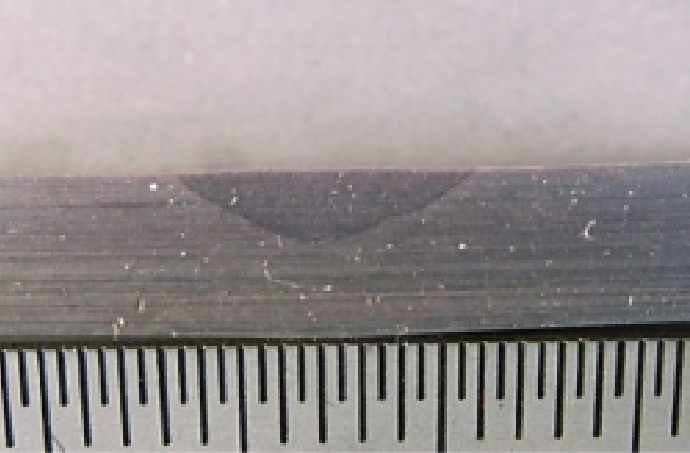

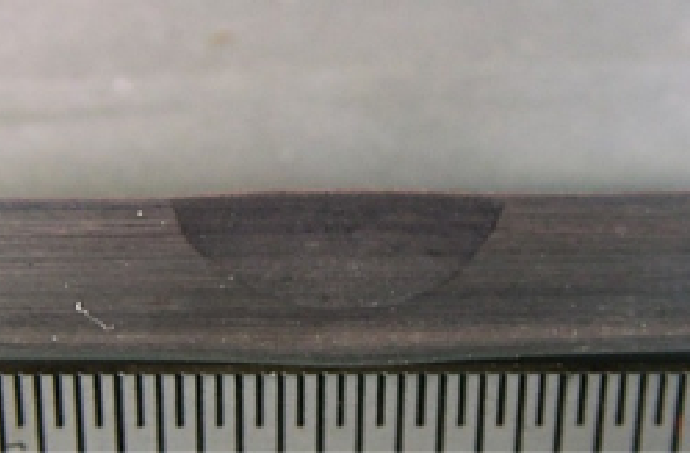

| Hi-Almate (helium added) | Argon |

|---|---|

|

|

| Hi-Almate | Argon Gas |

|---|---|

|

|

Welding conditions Material: A5052, Current: 120 A, Fluctuation width: ±3 mm, Voltage: 19 V

| Hi-Almate | Argon Gas |

|---|---|

|

|

Welding conditions (drift, temporary attachment, bevel accuracy), MIG welding

Material: A5052, Current: 120 A, Fluctuation width: ±3 mm, Voltage: 19 V

Joining and Cutting Technologies Product List