Machinery / Environment

Aquablaster (Diffusion Pipe)

High quality, high performance diffusion pipe for improving water quality as part of waste water processing. Reliably traps odors and dust using high oxygen dissolution performance.

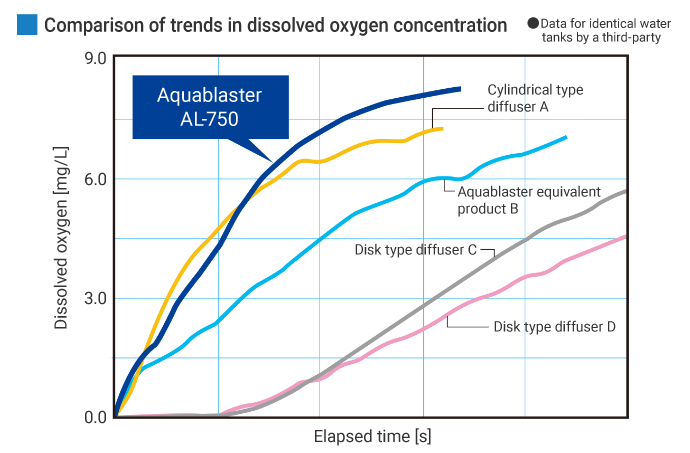

Differences to Other Diffusion Pipes

1Reliably Catches Odors and Dust

Has a higher oxygen dissolution performance compared to other products.

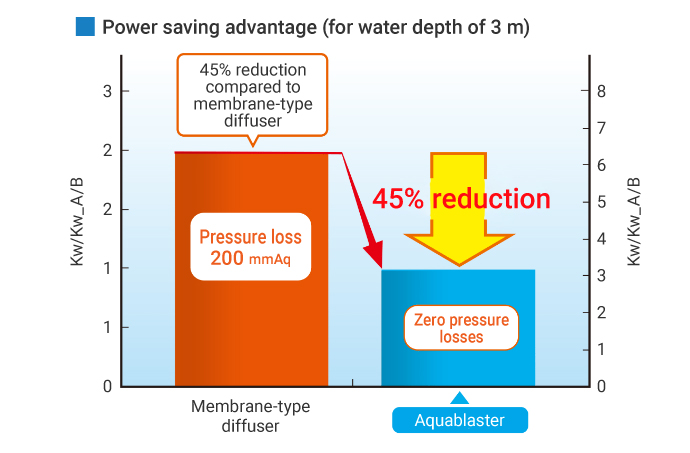

2Reduced Electricity Costs

Compared to membrane-type diffusers, the absence of pressure losses gives energy-saving effects that reduce power consumption.

Source: Aience Inc.

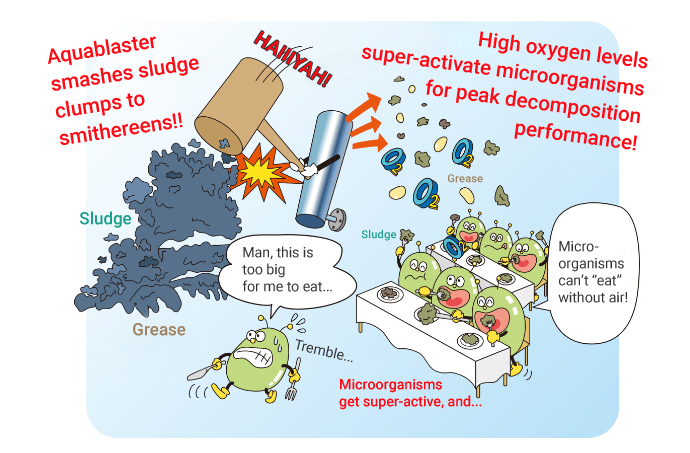

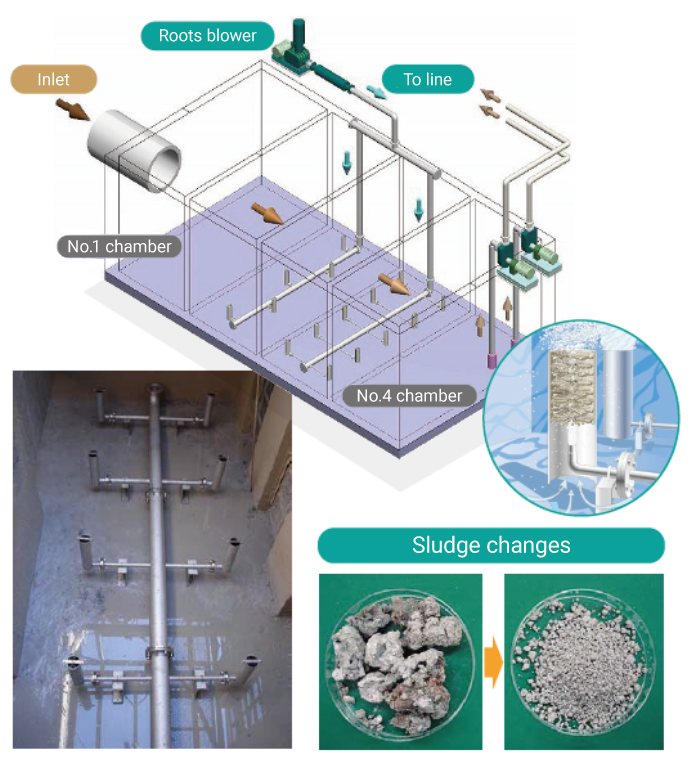

3Reduced Sludge Output

Sludge volume is reduced as suspended solids (SSs) and oil components are crushed into particles small enough for microorganism digestion. Sludge pulverization is prevented by adjusting the air volume.

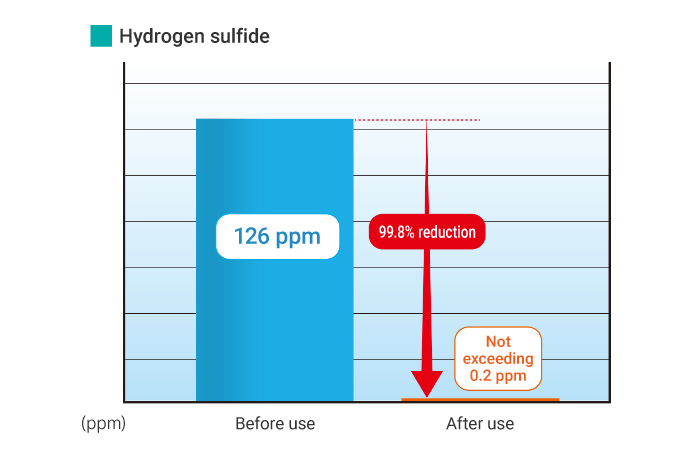

4Zero Odor Generation

Microorganisms are made to perform full aerobic respiration metabolism so that no odors such as hydrogen sulfide are generated. (Limited to installations designed by Iwatani.)

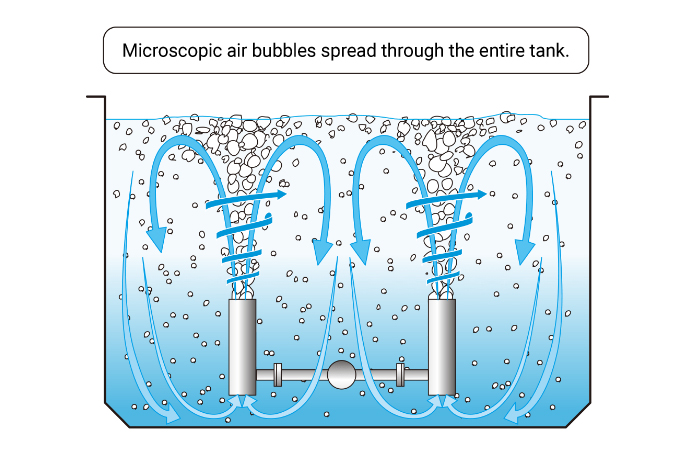

5Powerful Stirring Inside Tank

Sludge at the bottom is swept up to prevent accumulation and eliminate anaerobic areas. Also prevents substances such as silica and calcium from settling.

6Ais Eliminates Pressurized Flotation Unit

If a tank exists in which pre-processing can be performed by Aquablaster, pressurized flotation can also be eliminated.

Examples of Applications

- Reducing circulating water waste from painting booths

- Improving food waste water quality

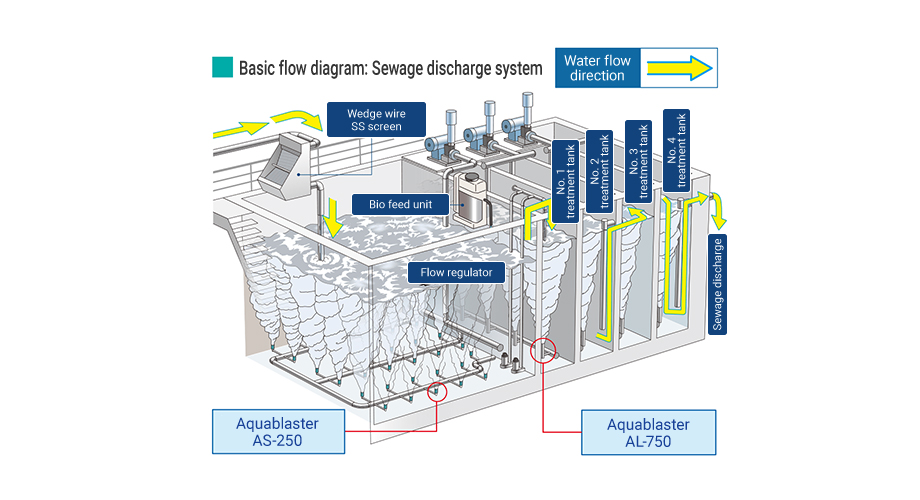

Example Painting Booth Installation

Automotive Painting Line Circulation Water Purification Example

Cost Reductions for Company a Automotive Plant

Units (JPY)

| Before Installation | After Installation | |

|---|---|---|

| Cleaning Costs | 4,500,000 | 900,000 |

| Waste Treatment Costs | 9,900,000 | 1,320,000 |

| Waste Water Treatment Costs | 840,000 | 168,000 |

| Electrical Costs | 0 | 1,944,720 |

| Activator | 0 | 2,400,000 |

| Total | 15,240,000 | 6,732,720 |

| Cost Reduction | Cost reduction of JPY8,507,280 per year | |

Source: Aience Inc.

Water Quality Changes for Automotive Plant Painting Circulation Water (Units: MG/L)

| Circulation Water Replacement Guideline | Raw Water | After 1 Month | After 2 Months | After 4 Months | |

|---|---|---|---|---|---|

| BOD | - | 270 | 1,100 | 1,960 | 1,440 |

| COD | - | 140 | 1,560 | 2,220 | 3,130 |

| SS | 2,000 | 100 | 156 | 1,710 | 1,900 |

| N-Hex | - | 24 | 24 | 56 | 26 |

| PH | - | 6.7 | 6.7 | 6.3 | 6.1 |

| Viscosity (M/S) | 10.0 | 1.0 | 1.5 | 8.0 | 6.9 |

Please inquire for more information on environmental systems.

Environmental Plant Department

Tokyo

81-3-5405-5811

Osaka

81-6-7637-3181