Machinery / Environment

Solvent Regeneration System

Cleaning fluid (waste solvent) discharged from manufacturing plant production processes is treated as waste material. The use of solvent regeneration systems (solvent recycling systems) allows the recycling of high-purity recovered solvent.

Advantages of Solvent Regeneration

- Reduced operating costs

The time taken to recover initial investment costs varies depending on solvent processing volumes and type, but solvent processing costs can be dramatically reduced. - Reduced CO2 emissions

Solvents treated as industrial waste leads to reduced CO2 emissions, through reductions in combustion processes

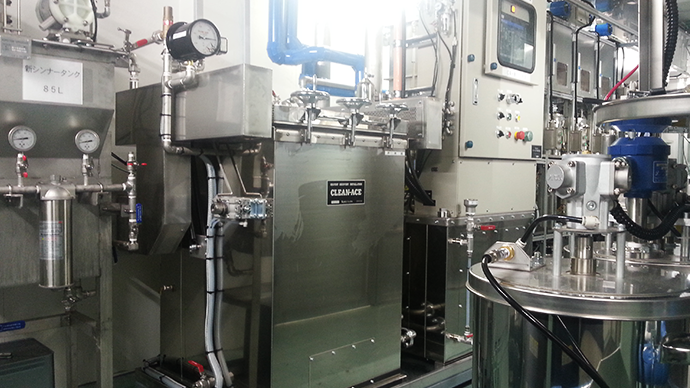

CA100 Series Compact Solvent Regeneration System

Clean-ACE101 Series Solvent Distillation Regeneration System Clean-ace103v Series Vacuum Distillation Regeneration System

Ideal for recycling waste thinner stored in 18 liter cans.

-

- Processing capacity:

- 15 to 30 L/cycle

-

- Compatible solvents:

- Class 1 petroleum substances (e.g., thinner, toluene, acetone, MEK, ethyl acetate), alcohol (e.g., methanol, ethanol, IPA), fluorocarbons, chlorine-based solvents

CA102 Compact Continuous Solvent Regeneration System

Can be combined with a cleaning unit for continuous distillation of alcohols.

-

- Processing capacity:

- 5 L/h

-

- Compatible solvents:

- Thinner, toluene, ethyl acetate, alcohol, ketones, chlorine-based substances, fluorocarbons

CA811 Series Vacuum Distillation Recovery System (ca811j Normal-Pressure Model)

Ideal for regenerating cleaning solvents containing resin or paint from reaction tanks or tanks used in manufacturing (approx. two bucket-size cans).

-

- Processing capacity:

- 30 to 60 L/cycle

-

- Compatible solvents:

- Class 1 petroleum substances (e.g., thinner, toluene, acetone, MEK, ethyl acetate), alcohol (e.g., methanol, ethanol, IPA), fluorocarbons, chlorine-based solvents

CA800 Series Vacuum Distillation Continuation Recovery System

Automatic Regeneration From Drum Cans Ideal for Removing Paint and Ink Resin

Ideal for continuous regeneration of solvents from printing machine cleaning units and automatic continuous processing from drum cans.

-

- Processing capacity:

- 10 to 200 L/h continuous

-

- Compatible solvents:

- Class 1 petroleum substances (e.g., thinner, toluene, acetone, MEK, ethyl acetate), alcohol (e.g., methanol, ethanol, IPA), fluorocarbons, chlorine-based solvents

CA900 Series Vacuum Distillation Continuous Recovery System

Capable of Continuous Automatic Regeneration Ideal for Removing Machining Oil and Other Fluid Substances

Ideal for continuous regeneration of hydrocarbon cleaning fluid containing waste oil discharged from cleaning systems, kerosene, and waste alcohol.

-

- Processing capacity:

- 10 to 200 L/h continuous

-

- Compatible solvents:

- Alcohol (e.g., methanol, ethanol), chlorine-based solvents, fluorocarbons, Class 1 petroleum substances (e.g., toluene, acetone, MEK), Class 2 petroleum substances (e.g., kerosene, hydrocarbon cleaning fluid)

Please inquire for more information on environmental systems.

Environmental Equipment Department

Tokyo

81-3-5405-5811

Osaka

81-6-7637-3181