Iwatani Advanced Hydrogen Technology Center

Facilities

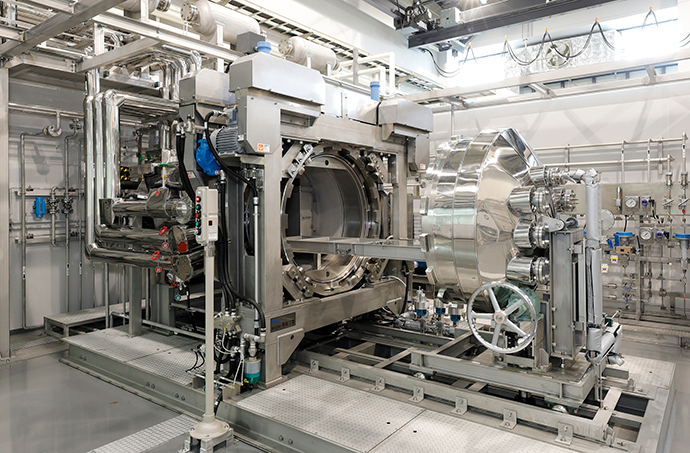

As a leading company in the hydrogen business, we started handling hydrogen in 1941, attained many research-based firsts for Japan, and pioneered new markets for liquid hydrogen involving high-capacity transportation and storage. As Japan’s sole supplier of liquid hydrogen, the Iwatani Advanced Hydrogen Technology Center serves as the base for our company’s technical research. The center is equipped with a testing environment unparalleled in Japan to allow the handling of liquid hydrogen at cryogenic temperatures of -253°C and ultra-high pressure hydrogen gas pressurized up to 135 MPa. We have applied these advanced testing facilities to undertake a broad range of hydrogen research and development and to promote technological verifications for real-world applications.