Machinery / Robot Systems

Robots Example Robot Systems

In 1977, Yaskawa Electric Corporation became Japan’s first company to sell the all-electric MOTOMAN industrial robot. Later that year, after signing a distributor contract, Iwatani launched sales of arc welding robots, drawing on its expertise in welding technologies. In the more than 40 years since then, We have expanded the market through developing applications to address a wide range of needs, including spot welding, laser cutting, painting, assembly, and handling. We continue to respond to new challenges in the ever-growing industrial robot market to achieve automation and labor savings.

System Examples

Arc Welding Systems

These make possible high quality automated welding for the automotive and other industries. We offer total systems solutions from small and medium to large-scale welding processes, including peripheral equipment.

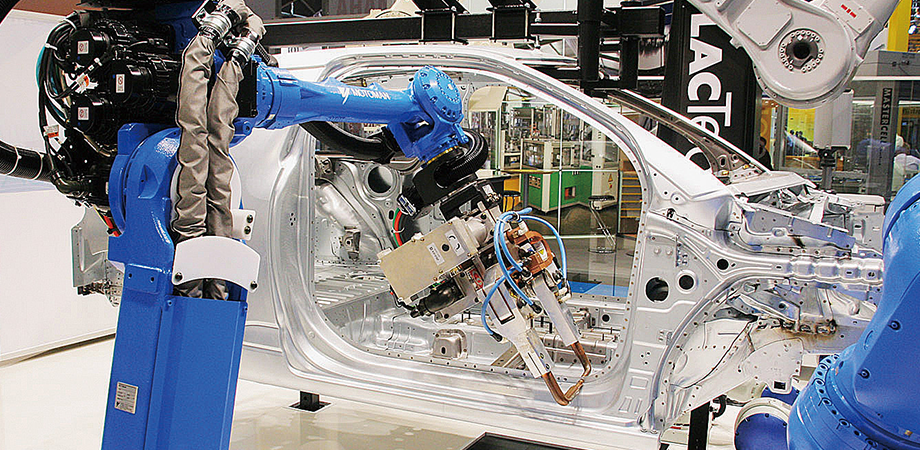

Spot Welding Systems

Spot welding is a key process in automotive production lines. Iwatani offers a wide range of solutions based on welding technologies developed over many years.

Handling Systems

Iwatani offers total systems solutions for a broad range of scenarios at production locations, including conveying large and small workpieces, positioning work, and insertion into and removal from machines, including hand jigs and peripheral equipment.

Picking and Packing Systems

Our systems allow high speed and highly precise automation of various operations to improve productivity, including food, container, and component sorting, arranging, packing, and serving.

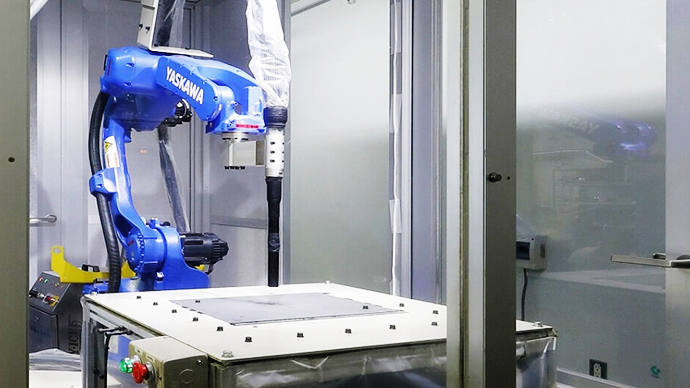

Collaborative Robot Systems (Assembly, Inspection, Welding)

These robots incorporate safety sensors to allow work alongside humans without safety fences. Certain types offer easy teaching functionality to reduce manpower requirements even in processes for which robot adoption was previously considered impractical.

Cleaning Processes (Dry Ice Cleaning, High-pressure Cleaning)

Dry ice cleaning is a cleaning technique that minimizes damage to the item being cleaned. Sublimation eliminates all traces of the dry ice cleaning agent. Incorporating this technique into a robot can realize more efficient cleaning.

Weld Visual Inspection Systems

These systems use a 3D camera to scan weld locations and analyze cross sections to automate visual inspections and storage of inspection data. This strengthens traceability and offers high quality control.

Please inquire for more information on robot systems.

Robot & FA System Department

Tokyo

81-3-5405-5925

Osaka

81-6-7637-3085

Robot system product list